Introducing a new product to the market is always a risky endeavor. Many different factors can derail a new product’s launch. One of the best ways of mitigating these risks is to adopt low-volume production. This refers to production runs that range from as few as 50 units up to 100,000 units. By comparison, high-volume production can run into hundreds of thousands or even millions of units. This article will describe when to use low-volume production and outline the key advantages of this manufacturing philosophy.

When is Low-Volume Production Used?

There are many reasons to shift focus to low-volume production. In some cases, the aim is to improve manufacturing efficiency while other times it’s merely a necessity of bespoke industries. Improvements take the form of better production testing, reduced tooling, minimization of cost, and shifts toward flexible manufacturing. These are described in more detail below.

Low-volume production is often used to bridge the gap between product development/ prototyping and full-scale production. It is a low-risk method of ironing out manufacturing or assembly issues that didn’t get picked up during the initial prototyping phase. From the low-volume starting point, production can gradually be ramped up and the manufacturing processes optimized along the way. As an added benefit, this all happens before sinking significant sums into expensive tooling.

Another reason to implement low-volume production is to gauge the market’s response to a new product. Instead of investing significant amounts on expensive high-volume tooling for the mere hope of success, small numbers of products can be put out first to gauge how consumers respond. These products can be released in a controlled manner to a select group specifically for testing or they may be released into the market and their commercial success used to gauge market adoption.

Some products can only be profitable if manufactured in large numbers using automated manufacturing processes. However, this requires a significant upfront capital investment, making it a financially risky proposition. Low-volume production technologies require very little up-front investment and can be used to test the product’s popularity before committing to full-scale production. If the market is relatively small, then the manufacturer may not need to move beyond low-volume production at all.

The demand for customized products has risen dramatically in recent decades. Tailor-made products designed specifically to fit a customer’s preferences will always be more desirable than one-size-fits-all items. However, by their very nature, custom products cannot reasonably be manufactured using high-volume production techniques. Instead, low-volume production techniques offer far more flexibility and customizability.

Benefits of Low-Volume Production

No matter why low-volume production gets adopted, it generates several distinct advantages.

Faster Manufacturing Response Time – Low-volume production technologies can come online much quicker due to their inherent flexibility. For example, it may take months to design an injection mold whereas a 3D printer may turn out an alternative in just an afternoon.

Reduced Inventory Requirements – Low-volume production fits hand-in-glove with just-in-time inventory management systems. The low-volume manufacturer doesn’t need to keep large inventories of spare parts or sub-components on hand the way mass-production operations often do.

Faster Market Penetration – Staying ahead of the competition is difficult in today’s fast-paced environment. Any new product idea can be quickly copied and produced at scale before its original creator has the chance to penetrate the market. Low-volume production techniques are the best way to get the product to consumers quickly.

Reduce Production Faults – Large-scale manufacturing often unearths a wide range of issues that weren’t caught during prototype development. These could range from inconsistent manufacturing processes, material shortages, or even assembly issues. Low-volume production can help catch these problems before they infect the more expensive high-volume tooling.

Allow Design Flexibility – Design or performance deficiencies may not be discovered until after the product has been released. Alterations to the design are simple with low-volume production as there is no need to modify expensive tooling or reorganize complex production processes.

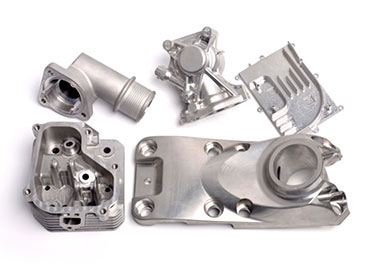

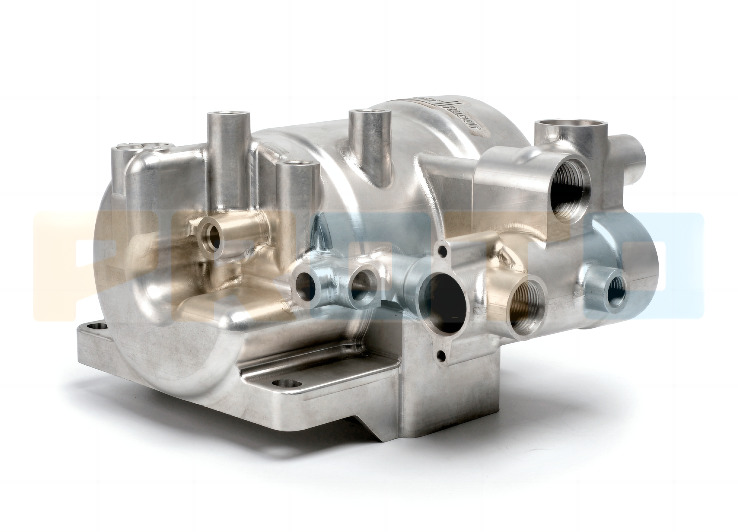

Typical Low-Volume Production Technologies

Low-volume production can leverage a wide range of technologies to quickly and economically manufacture parts. A few of the most common are detailed below:

CNC Machining – CNC machining is ideal for low-volume production as the machine can be set up relatively quickly. Parts can be continually manufactured either manually (with an operator changing tools and material) or automatically (with an automated tool changer and robot-controlled palletized systems to load material into the machine and remove completed parts).

Urethane Casting – Urethane casting is a great way to manufacture plastic parts when complex injection molds are too expensive. The process doesn’t require high temperatures and pressures so it can be done with cheaper equipment.

Additive Manufacturing – Additive manufacturing/3D printing has come a long way from its early days when it was tied solely to rough prototyping. New technologies can generate functional parts that are reinforced with carbon fiber or fiberglass to increase strength. Metal printers can also produce high-quality steel parts without the need for expensive 5-axis CNC machines.

Is Low-Volume Production a Good Fit for Me?

When it comes time to decide which production philosophy to follow, it helps to fully define the task. Many facets come into play — the manufacturing complexity, the commercial environment into which the product is being marketed, and the preferred time frame are some of the biggest. Low-volume production is ideal for situations where market adoption is not guaranteed, when competitors might copy the product, or if a limited production run is required. To learn how you might benefit from low-volume production, contact a PROTO MFG expert or get your instant quote today.