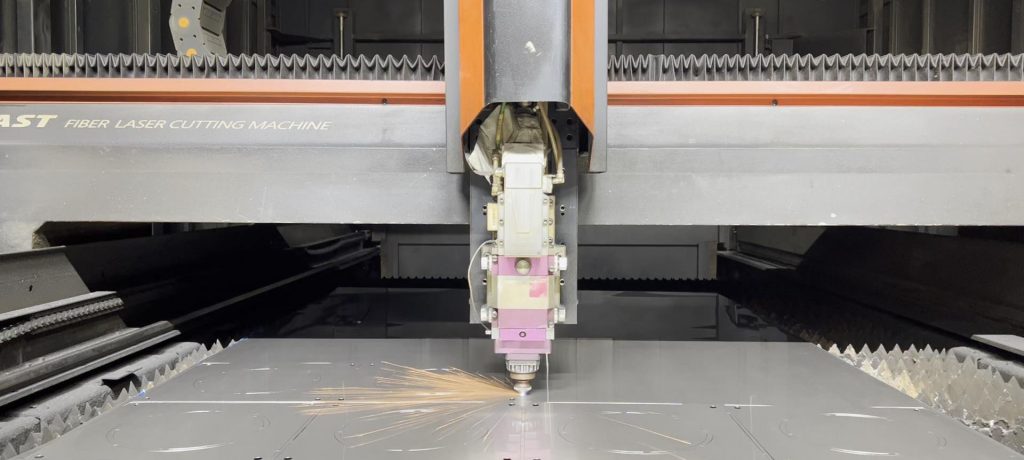

At one time, lasers were nothing more than science fiction dreams. In the last 60 years, we’ve transitioned from imaginary cosmic ray guns to harnessing the power of light strategically. Today, lasers are everywhere, in subtle surgical equipment, optical media readers, and in the brute-force strength of lasers for manufacturing. What all of them have in common is the ability to do their work with incredible precision, guided by a steady hand, or a computer-controlled application.

What is a LASER?

LASER stands for Light Amplification by Stimulated Emission of Radiation. Essentially, lasers work by exciting atoms of certain elements in a controlled environment. The electrons in those atoms shift positions in their orbit around the nucleus to a more energetic path and when they move back to their “home” position, they release a stream of coherent light energy, meaning that the light is the same wavelength and is entirely in phase. The energy consists of photons, which are guided through a lens. There, they concentrate into a single stream, and their power is substantial.

Two things affect a laser’s cutting ability: the power of the laser (measured in kilowatts, or kW) and its ability to focus its beam as compactly as possible. For designers, it’s essential to know that the laser, like any cutting instrument, has a width to it, called the laser kerf. While it’s important to compensate for it, the kerf is much smaller compared to other cutting processes.

Comparing Lasers for Manufacturing

Two types of lasers dominate the manufacturing sector, carbon dioxide (CO2) and fiber (also known as a solid-state laser). Although both were invented around the same time (1963/64), CO2 has been used for a longer time in commercial applications. Fiber really didn’t arrive on the manufacturing scene until the early 1980s.

Comparing the two, fiber generally leads the way, but the choice regarding which to use is often based on the type and thickness of the material you’re cutting. Fiber is faster on thinner metals. It’s more highly-focused beam also helps these lasers more quickly cut through highly reflective materials. Unlike CO2 lasers, fiber lasers have no moving parts or mirrors to go out of whack, yielding lower maintenance costs. Best of all, fiber lasers use less electricity for the same cutting power.

You’d think that the decision to use fiber would be a slam-dunk, but there are areas in which CO2 still impresses, such as the speed of straight cuts and, for now, material thicker than 0.2 in. (5mm). That said, fiber lasers are getting more powerful, so even these differences are becoming less significant.

Alternatives to Laser Cutting

With all of their power and speed, you’d think that lasers are the only way to go, but there are other strong competitors.

Milling: Using an end mill to cut seems kind of old school, but it’s accurate to within 0.0003 in. (0.00762mm) and is reasonably fast. What’s best about it is the high-quality edges end mills create and the ability to work with 3D media. A downside to milling is that set-up and programming take time.

Waterjet: Combine water with an abrasive powder, fire it out of a nozzle using ridiculously high pressure, and you have waterjet cutting. It’s as accurate as milling, but edge quality is sacrificed somewhat due to distortion of the water stream as it slices through the metal.

Wire EDM: In Wire Electrical Discharge Machining (EDM), electricity feeds through a thin, charged wire (typically copper or brass), which causes a spark to form between it and the material you’re cutting. The circuit is completed with another wire on the opposite side of your metal. The spark penetrates the metal, precisely cutting through it, and that second wire completes the circuit. The whole process sits in dielectric water, a type of water that doesn’t conduct electricity, so it serves to cool the cutting surface while limiting path of the electrical flow between the wire and the metal. It’s a slow process, but what it lacks in speed, it makes up for with accuracy within 0.0001 in. (0.00254mm). One important limitation: Wire EDM requires that the metal your part is made from must be electrically conductive or it won’t cut it.

Punch Press: This process does just what you think. A press punches through your metal to create the desired form. Some sacrifices with this process are accuracy and edge quality. Your part will certainly need deburring. You also can’t use it if your metals are brittle or hardened as the part will break while in the press. On the positive side, while it takes time to set up and program a punch press, once you have that nailed down, it’s easy to make multiple parts.

Laser Cutting Service for Sheet Metal Parts

Analog and digital manufacturing technologies have merged in the form of laser/punch machines. These combine the precise, powerful cutting of a fiber laser with standard tooling options and geometries that are best managed by a punch press. Features such as louvers, flanges, and more can be created quickly with laser-cut, burr-free edges using a single tool for both cutting and forming.

The addition of lasers in manufacturing has added a safe, rapid, and accurate means of cutting sheet metals. The power of the laser combined with its ability to shift smoothly from the brute force of cutting in straight lines to the subtle precision of creating gentle curves, makes them an indispensable tool in a machinist’s toolbox and a boon for designers of complex parts.

Summary

This article explains the laser cutting and discusses the details and uses of each. If you would like to learn more about laser cutting please contact a PROTO MFG representative.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.