Metal die casting is a systematic process for producing a wide range of metal parts. This technique makes it easier to produce strong, precise, lightweight metal components at a lower cost. The parts or components produced by the die casting process facilitate the production of both consumer and industrial components.

Although metal die casting is a flexible manufacturing process, it is recommended that you have a good understanding of the technique before using it on your own or employing companies that provide related services. So what is die casting, how does it work and what are the different types and benefits? Read on to find out.

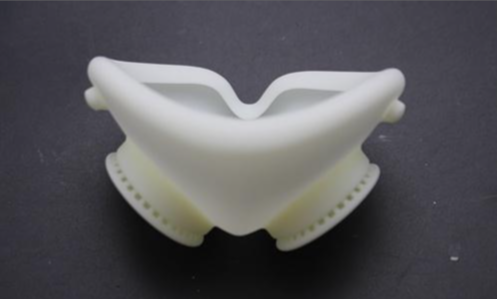

Die casting is the process of using high pressure to force molten metal into a mould. A hydraulic press, which ensures that the closing surfaces meet almost perfectly to form a seal, forces together the hardened tool steel pieces that make up the cavity.

Metal die casting allows the production of precision metal parts with excellent finishes and accurate dimensions. It is ideal for high volume production because of its ability to create complex parts.

Aluminium is a primary metal in die casting, used in alloys for the cold chamber die casting process. These aluminium alloys typically contain elements such as magnesium, copper and silicon.

Aluminium-based die casting alloys are an excellent choice for intricate, finely detailed parts because they are lightweight and offer excellent dimensional stability. They have robust resistance to temperature changes, corrosion, electrical and thermal conductivity. Here are some commonly used aluminium die casting alloys.

Zinc alloys make up a significant proportion of die casting metals. They are easy to manufacture, suitable for hot chamber die casting and offer additional benefits such as impact strength, ductility and plating compatibility. Here are some typical alloys used in zinc die casting.

The two most commonly used die casting processes are hot chamber and cold chamber. Each is unique and suitable for different scenarios. Here is what these two categories of processes involve:

The hot chamber die casting process is ideal for low melting point materials such as magnesium alloys, tin, zinc and lead. This is to prevent damage to the pump which could occur when it comes into contact with metals or alloys with a higher melting point. Injection of the molten metal into the mould is achieved by applying pressure from a hydraulic system.

Cold chamber die casting is the ideal method when working with high melting point materials such as aluminium. As the high temperature required to melt these materials can damage the pumping system, this process is perfect for such metals.

It is a high pressure die casting process in which the molten material is poured into a cold chamber and then injected into the mould. The hydraulic system used in a cold chamber process is similar to that used in a hot chamber process. However, a higher pressure of between 2000 and 20000 psi may be required.

The following variations were suitable for dealing with defects, mishaps, distortions and other problems that could occur during the casting process.

Good mechanical properties: Die casting produces parts with good mechanical strength, although not as strong as forged parts. It can also produce parts with improved conductivity, hardness and durability.

Are you looking for a reputable partner for your parts fabrication and machining projects? Look no further. At PROTO MFG, we specialize in CNC machining and related technologies, including sheet metal fabrication, rapid prototyping, Die Casting, etc. Whether it is a project with a simple design or parts with complex geometries, do not hesitate to contact us today!