CNC is a computer that runs numerical control software, and executes part or all of the functions of the numerical control device according to the CNC machining program of the part, and the only device outside the computer is the interface.

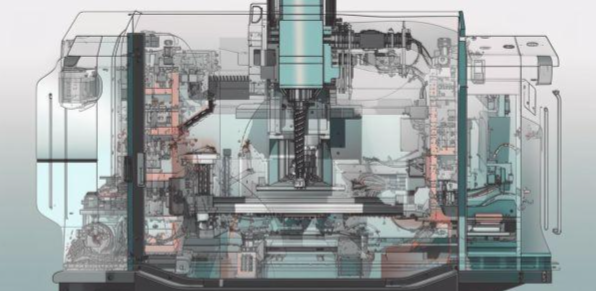

The CNC numerical control system is composed of machining program, input and output equipment, CNC device, programmable controller (PLC), spindle drive device and feed drive device.

The CNC numerical control system is in strict accordance with the CNC numerical control program for automatic processing of the workpiece. The CNC machining program records various information required for machine tool processing according to the order of parts processing, such as the trajectory information of parts processing, process information and switch commands.

The working process of a CNC device is the process of executing software with the support of hardware. The working principle of the CNC device is: through the input and output equipment input of various data information (CNC machining program) required for machining parts of the machine tool, through the computer decoding, tool radius compensation, acceleration and deceleration control, interpolation and other processing and calculation, the moving component of each coordinate axis is sent to its corresponding driving circuit, after conversion and amplification, the servo motor is driven, the coordinate axis is driven, and real-time feedback control is carried out at the same time, so that each coordinate axis can be accurately moved to the position required by the instruction. In this way, the relative movement of the tool and the workpiece is realized, and the processing of the part is automatically completed.