In industrial applications, manufacturers commonly use several standard Hard Anodizing Color. The specific shades of these colors can vary depending on the specific alloy being anodised and the process parameters used. Manufacturers commonly achieve the following colors through anodising:

This colourless, transparent finish provides good corrosion resistance and protects the underlying metal from further oxidation.

Manufacturers achieve this dark matte black finish using a black dye. Manufacturers often use black anodising for decorative purposes and to reduce glare on anodised aluminium surfaces.

Manufacturers produce this light to medium gold color using a yellow dye. Manufacturers often use gold anodising for decoration and to enhance the appearance of anodised aluminium surfaces.

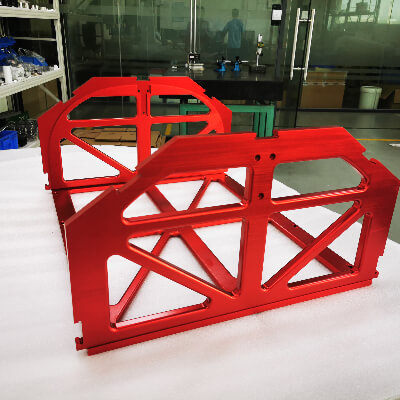

Manufacturers achieve this vibrant crimson color by using red dye in the anodising process. Manufacturers often use red anodising for decoration and to enhance the visibility of aluminium parts.

Manufacturers achieve this medium dark blue color by using a blue dye in the anodising process. Manufacturers often use blue anodising to decorate and enhance the appearance of coloured anodised aluminium surfaces.

Manufacturers produce this light to medium green color by using green dye in the anodising process. Manufacturers often use green anodising to decorate and enhance the appearance of aluminium surfaces.

It is important to remember that the appearance of these standard Hard Anodizing Color will vary depending on the specific dye used and the thickness of the anodising layer. In addition, custom colours can be achieved through anodising, including purple, pink and bronze.

PROTO MFG is your custom manufacturing operating system that makes sourcing parts faster, easier and more efficient.