Metals

What Are the Sheet Metal Forming Processes?

Mar,20 2024

Discover the secrets behind the sheet metal forming processes and revolutionize your manufacturing techniques.

Unveiling the Contrast: Sheet Metal vs Fabrication

Mar,20 2024

Unveiling the Contrast: Sheet Metal vs Fabrication

What are the 5 basic weld types?

Mar,20 2024

Unlock the secrets of welding with our guide to the 5 basic weld types. From MIG to TIG, learn the techniques you need to know.

What is best for metal fabrication?

Mar,20 2024

Discover the ultimate techniques and materials for metal fabrication. Find out what is best for metal fabrication.

Deciphering the Difference: Fabrication vs Welding

Mar,20 2024

Deciphering the Difference: Fabrication vs Welding

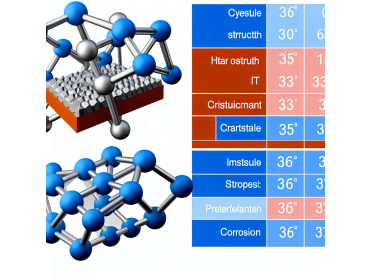

Choosing Between 316 vs 304 Steel: Which is Best?

Mar,20 2024

Choosing Between 316 vs 304 Steel: Which is Best?

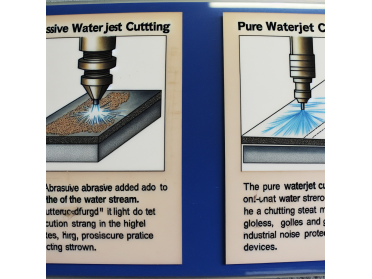

Abrasive vs Pure Waterjet Cutting: Which Is Superior?

Mar,20 2024

Discover the ultimate showdown between Abrasive vs Pure Waterjet Sheet Metal Cutting to determine the superior method.

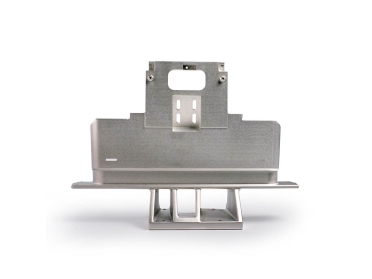

Essential Sheet Metal Fabrication Materials

Mar,20 2024

the key materials used for sheet metal fabrication - stainless steel, hot rolled steel, cold-rolled steel, aluminium, brass, copper.

3D Printing vs Injection Molding: Which is Better?

Mar,19 2024

Compare the game-changing methods of 3D Printing vs Injection Molding to see who comes out on top.

Bead blasted

Jul,03 2023

Bead blasting is a surface treatment process that involves propelling abrasive media at high speed onto a workpiece's surface, creating a roughened, matte appearance. The process has become increasingly popular in various industries, including aerospace, automotive, and construction. Bead blasted type offers several material properties that make it ideal for different applications, including resistance to corrosion, wear, and galling. In this blog post, we will delve into the different types of bead blasting, their material properties, available processing methods, and industry and parts applications.

Threaded Inserts

Jul,03 2023

Threaded inserts are widely used components that enhance the functionality and effectiveness of mechanical products. These inserts provide a reliable and efficient fastening solution for a range of applications in different industries. If you're a mechanical engineer, a buyer, or a designer looking to enhance your knowledge of threaded inserts, this comprehensive guide is for you. In this blog post, we will provide a detailed overview of threaded inserts, the types, material properties, processing methods, and industry and parts applications. By the end of this guide, you'll be well-equipped to make an informed decision on threaded inserts that best meet your needs.

Mold Texturing

Jul,03 2023

Mold texturing is a crucial aspect of plastic manufacturing that affects the overall look, feel, and functionality of the final product. Understanding the different types of textures, material properties, processing methods, industry applications, and parts applications is important to select the right mold texturing solutions for specific product requirements. By having a better understanding of the mold texturing process, mechanical engineers, buyers, and designers can make informed decisions while selecting the best mold texturing solution to meet their needs.