Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts.

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

Our sheet metal fabrication facility, along with a team of experienced engineers, ensures that each part is manufactured to precise specifications and quality standards.

Laser cutting utilizes a high-energy laser beam to cut materials into desired shapes.

Bending is accomplished by positioning the metal sheet on a bending machine and applying pressure to shape it as desired.

Welding involves heating the metal to its melting point and using appropriate welding materials to join metal components together.

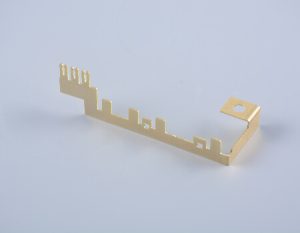

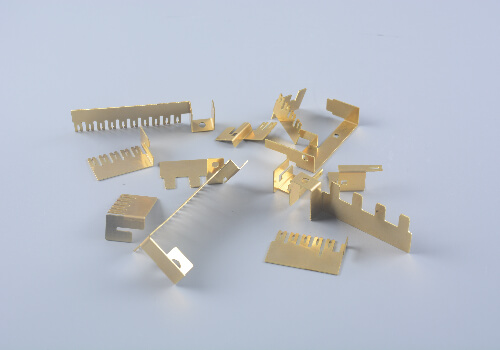

We’ve been manufacturing various sheet metal parts for different clients, whether simple or complex. Please review the sheet metal parts we’ve previously produced.

Upload CAD file

Securely upload your part design to our online quote builder

Receive instant quote

Our engineers provide precise quotations for you

Production

Procure materials and produce parts according to the quantity required

Quality control

Quality inspection department inspects the parts according to the drawings

Delivery

We stock a variety of metal materials suitable for various part applications and industries. Available materials include aluminum, brass, stainless steel and steel alloy for metal parts.

Cold-rolled sheet SPCC is mainly used for electroplating and baking varnish, which is low in cost, easy to form, and has a material thickness of ≤3.2mm.

Hot-rolled sheet SHCC, material T≥3.0mm, is also made of electroplating and baking varnish parts, which is low in cost, but difficult to form, mainly flat parts.

SECC electrolytic plates are divided into N material and P material. N material is mainly not used for surface treatment, which has high cost, and P material is used for sprayed parts.

It is mainly used as conductive material, and its surface treatment is nickel plating, chrome plating, or no treatment, and the cost is high.

Aluminum plate generally use surface chromate (J11-A), oxidation (conductive oxidation, chemical oxidation), high cost, silver plating, nickel plating.

Aluminum profiles materials with complex cross-sectional structures, which are widely used in various sub-boxes. The surface treatment is the same as that of the aluminum plate.

Stainless steel is mainly used without any surface treatment, and the cost is high.

Enhance part performance by selecting surface finishes that improve the roughness, hardness, chemical resistance, and cosmetic features of the finished component.

Get instant CNC quotes by uploading your design files, including color, material, surface treatment, and required quantity, without the need to write a quote request email.

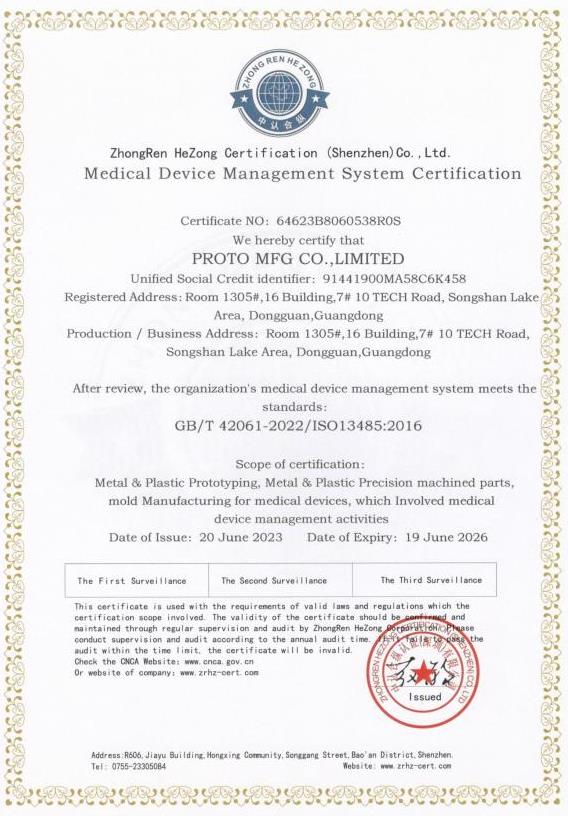

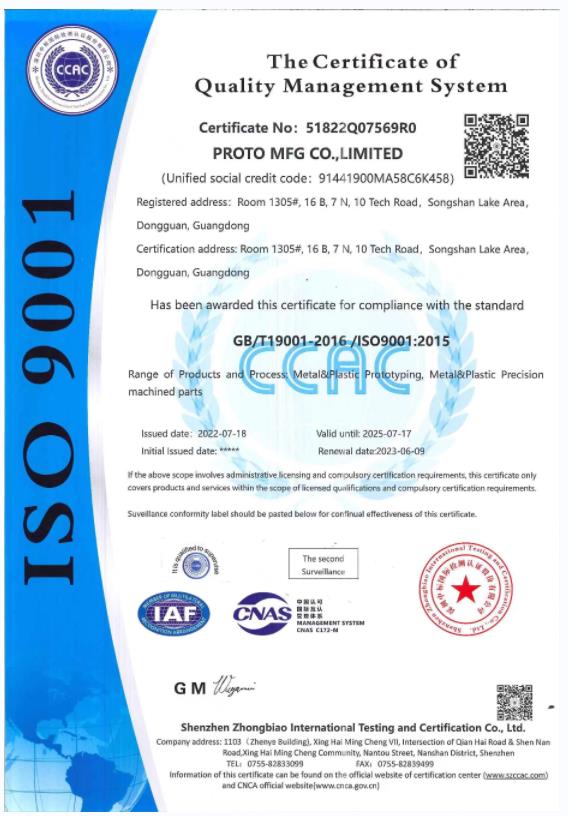

PROTO MFG’S CNC Machines are built to provide maximum accuracy whether they are tasked to produce one metal machined part or thousands of machined parts.

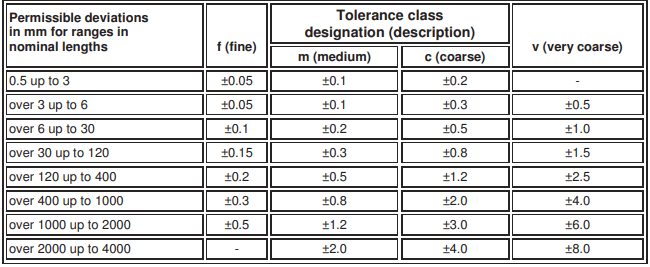

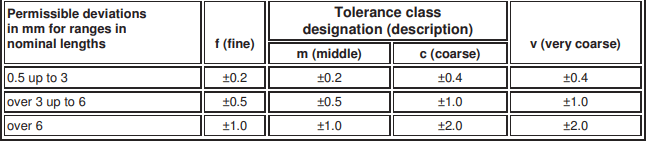

PROTO MFG’S tolerance Can be 0.005 to 0.01 mm

Direct from CNC machining factory, offering cost-effective solutions for your precision parts needs.

According to the difference in the structure of sheet metal parts, the process flow can be different, but the total does not exceed the following points.

Cutting ; Fitter ; Flanging ; Punching machine ; Pressure riveting ; Bending ; Welding

Sheet metal is a process for thin metal sheets (usually below 6mm), including bending, punching/cutting/compositing, folding, welding, riveting, splicing, forming (such as automobile body, computer body), etc. Its remarkable feature is that the thickness of the same part is consistent. Products processed by sheet metal technology are called sheet metal parts.

1. High production and processing efficiency

2. Remarkable results

The cutting in PROTO MFG sheet metal processing is non-contact laser cutting, and the outer edge heating has little interference, which can avoid the adverse effect of thermal expansion on the product workpiece. It can suppress the collapsed outer edge caused by laser cutting of raw materials, and generally does not need to be processed again, which improves the work efficiency to a certain extent.

3. Not limited by material properties

The state-of-the-art equipment of PROTO MFG enables sheet metal processing to quickly produce aluminum profiles and carbide, regardless of hardness, which can be laser cut without distortion. The production and processing flexibility is also very good, not only can handle any graphics but also can cut pipelines and other various materials. Most non-metallic materials can also be processed quickly and efficiently.