Quality Control for Custom CNC Machined Parts

Are you looking for a reliable and cost-effective way to ensure the quality of custom CNC machined parts? Is it important that high production standards are met throughout your entire manufacturing process? If so, having an effective quality control workflow in place is critical. Quality Control (QC) solutions like those used in the CNC Machining industry help identify process issues quickly and accurately, helping keep manufacturing costs down and customer satisfaction levels high. In this blog post we will discuss what role QC plays in producing custom machined parts as well as provide tips on how to set up an effective QC workflow that can help boost your productivity and improve product quality.

Understand the importance of Quality Control for custom CNC machined parts

In the PROTO MFG of custom CNC machining, quality control can make all the difference. From aerospace to medical devices, precision-made parts are an essential component of many industries. That’s why it’s crucial to ensure that each and every part meets the highest standards before it finds its way to the end user. Quality control entails a series of checks and balances to confirm that all parts meet the client’s specifications and are free of defects or errors. It’s a vital step in the production process that saves time, money, and reputation. By maintaining strict quality control protocols, CNC machine shops can guarantee the highest levels of accuracy, reliability, and customer satisfaction. Whether you’re manufacturing a prototype or producing a run of thousands, quality control is non-negotiable.

Learn about ISO quality standards and how they apply to custom CNC machining

ISO quality standards are integral to ensuring precision and consistency in custom CNC machining processes at PROTO MFG. As a set of international guidelines, these standards help manufacturers achieve a high level of quality control in all aspects of production, from design to delivery. Compliance with ISO guidelines ensures that each CNC-machined component is equal in terms of measurements, tolerances, and other critical factors. By adhering to these strict quality standards, companies can ensure that the final product will be of the highest quality, meeting or exceeding customer expectations. From prototyping to production, CNC machining specialists can help ensure that products and components meet the necessary ISO standards, providing manufacturers and their clients with peace of mind.

Review common Quality Assurance (QA) processes used in custom CNC machining

Custom CNC machining is a highly technical process that requires precision and accuracy to meet the desired specifications. Quality assurance (QA) at PROTO MFG plays a crucial role in ensuring that the final product meets the required standards. There are several QA processes that custom CNC machining companies use to ensure the quality of the product. These include inspection and testing of raw materials, dimensional inspection, surface finish inspection, and statistical process control. Each of these processes has its own unique set of tools and techniques to guarantee that the final product is of the highest quality. In today’s competitive market, QA processes are essential to the success of any custom CNC machining business.

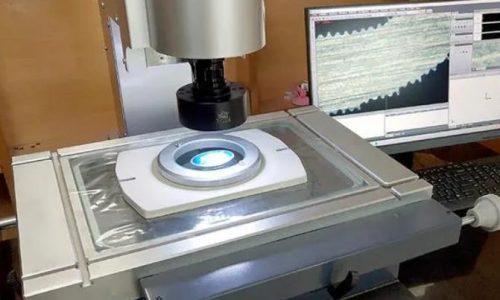

Examine the differences between manual and automated inspection processes

When it comes to quality control, inspection is a crucial step in ensuring that products meet certain standards. However, the process of inspection can have a big impact on efficiency and accuracy. Manual inspection relies on human judgement and physical examination, while automated inspection uses machines to carry out inspections. There are several key differences between manual and automated inspection processes, such as accuracy, speed, and cost. While manual inspection may be more flexible and better for detecting certain types of defects, automated inspection can be faster and more consistent. Ultimately, the choice between manual and automated inspection depends on the specific needs of the company and the product being inspected.

Understand the importance of precise measurement equipment and calibration practices

In any field that requires measurements, the accuracy and reliability of your equipment and tools cannot be understated. Precise measurement equipment and calibration practices are crucial in ensuring that the results you get are not only accurate but also repeatable. Whether you work in the healthcare sector, manufacturing industry or laboratory research, the use of correctly calibrated measurement equipment will allow you to maintain your industry standards, ensure compliance and make informed decisions based on trustworthy data. This is not only essential for the quality of your work but also for the safety of those around you. Proper calibration of equipment such as scales and thermometers can help minimize the risk of injury or harm to those who use your products or services. So the next time you think about cutting corners with equipment calibration, remember that the quality of your work and the safety of others could be at risk.

Explore commonly used QA software systems that keep track of production data

In today’s fast-paced business environment, it’s essential to have a reliable quality assurance (QA) system in place that can keep track of production data. Fortunately, there are plenty of software options available to choose from that are specifically designed to meet this need. These QA software systems are a crucial component of any successful manufacturing process, as they allow companies to monitor and analyze data on everything from raw materials to finished products. By doing so, they can identify potential issues, track progress, and make data-driven decisions that help improve efficiency and reduce waste. From cloud-based systems to robust on-premise solutions, there’s a QA software system out there to fit every company’s needs and budget. So whether you’re a small startup or a large corporation, now is the time to explore your options and start reaping the benefits of a powerful QA software system.

In conclusion, quality control is a critical element of custom CNC machining. Quality Assurance techniques have evolved over the years from manual processes to automated ones, and it’s essential for any CNC shop to have appropriate testing, inspection and measurement equipment in place. Additionally, QA software systems are available to streamline these processes and ensure better accuracy. While the exact quality control practices depend on the shop and its customer requirements, having standards set in place for incoming raw materials, in-process monitoring and final inspection can help ensure that all parts meet expectations when they leave the shop. Understanding these procedures and investing in reliable measuring devices are key to sound quality assurance processes and consistent product output.