A prototype is one or several functional prototypes that are made based on product appearance drawings or structural drawings without opening a mold, and are used to check the rationality of appearance or structure. With the advancement of science and technology, the rapid development of CAD and CAM technology has provided better technical support for prototype manufacturing, making accurate manufacturing of prototypes possible. So what are the categories of prototypes and what is the comparison between different categories? Let’s take a look below.

Classification of prototypes

(1) Manual prototype: The main workload is completed by hand.

(2) CNC prototype: Its main workload is completed with CNC machine tools. According to different equipment, CNC prototypes can be divided into:

a.RP prototype: It is mainly produced using laser rapid prototyping technology.

b.CNC prototyping: mainly prototyping produced by machining centers.

(1) Plastic prototypes: The raw materials are plastic, mainly prototypes of some plastic products, such as TVs, monitors, telephones, etc.

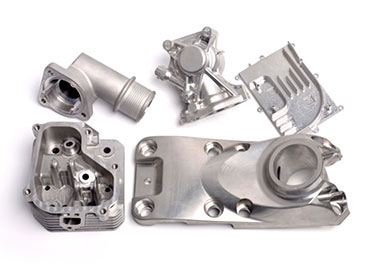

(2) Metal prototypes: The raw materials are aluminum-magnesium alloy and other metal materials, mainly prototypes of some high-end products. Such as laptop computers, high-end radio players, MP3 players, CD players, etc.

Comparison between RP prototype and CNC prototype

There are many categories of prototype models. Although CNC prototypes occupy a mainstream position in the prototype manufacturing industry, prototypes with other processing methods cannot be ignored. There are always applicable places. With the continuous advancement of science and technology, prototype processing methods with wider application, higher efficiency and higher precision will inevitably appear.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.