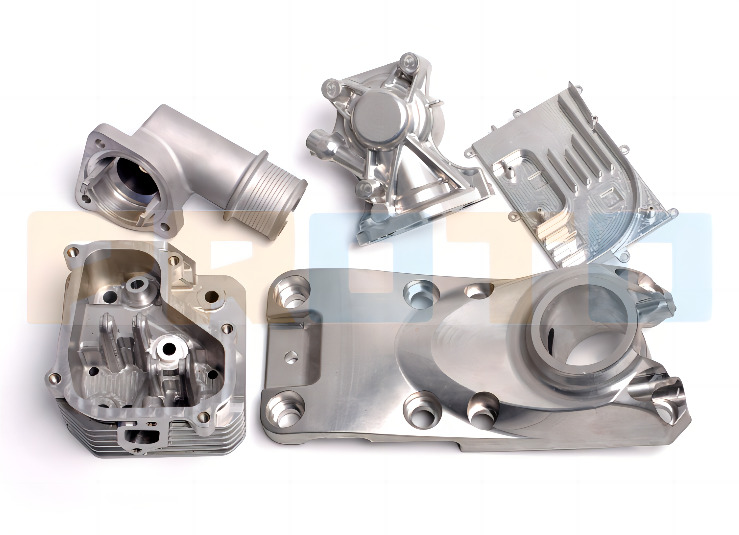

Aluminum alloy accessories and products are favored by many industries because of their light weight and exquisite appearance, and are increasingly used in industry and daily necessities. Especially in this era, as science and technology become more and more developed and society continues to progress, people’s demand for product diversity is getting stronger and stronger. Therefore, the better the craftsmanship of aluminum alloy products, the more people will like them, the greater the market demand, and the higher the efficiency. CNC processing is currently one of the best processing methods for aluminum alloy shell products.

In order to meet people’s demand for the diversity and high quality of aluminum alloy shell products, process skills must be summarized during the processing process. Based on many years of CNC processing experience, PROTO MFG summarizes the processing techniques that should be paid attention to in the processing of aluminum alloy shells.

The requirement for CNC machining skills is that the control system can logically process CNC machining programs with control codes or other symbolic instructions, and decode them by the computer, so that the machine tool can move and process parts. The blank is processed into a semi-finished product by cutting tools.

CNC cutting is a processing method that makes cutting more reasonable. It is also a common process for precision machining of aluminum alloys. Aluminum laser deep engraving technology uses end mills with multi-directional cutting functions, spiral cutting interpolation, contour cutting interpolation, etc. This way, it selects as few tools as possible to machine a small number of holes.

The ball end mill can be used with helical interpolation to continuously process tapered holes; the ball end mill and helical interpolation drill can be used for boring and chamfering; the end mill can be used with contour cutting interpolation to semi-process the hole. Finishing and precision parts processing; end mills for thread processing can be used for various thread hole processing by helical interpolation method.

If you are processing high-precision holes of any size for high-efficiency aluminum alloy precision parts, you can use the tool interpolation function. Especially when using high-speed milling, the load on each tooth is relatively light. Due to the aluminum laser deep engraving process, the same coated carbide end mill can be used for high-speed and high-precision hole processing in a variety of processed materials.

In CNC processing of aluminum alloy shells, the processing technology must be mastered.

Choose a reasonable cutting amount

Workers can choose the cutting speed based on the material being processed, hardness, cutting status, material type, and cutting depth. These conditions are necessary to effectively reduce machine wear.

Choose the right tool

When rough turning, generally speaking, it is best to choose high-strength and durable tools, so as to better meet the requirements of rough turning.

Choose a reasonable fixture

Parts must fully meet the needs of the machine to reduce unnecessary positioning errors. It is best to use special fixtures and clamping tools.

Determine a reasonable processing route

Keep processing routes as short as possible to reduce machine wear.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.