PROTO MFG is your ideal global manufacturing partner, offering extensive capabilities, dedicated teams for quality assurance, program management, and DFM consulting, with no minimum order quantities. Launch your new innovations successfully with us.

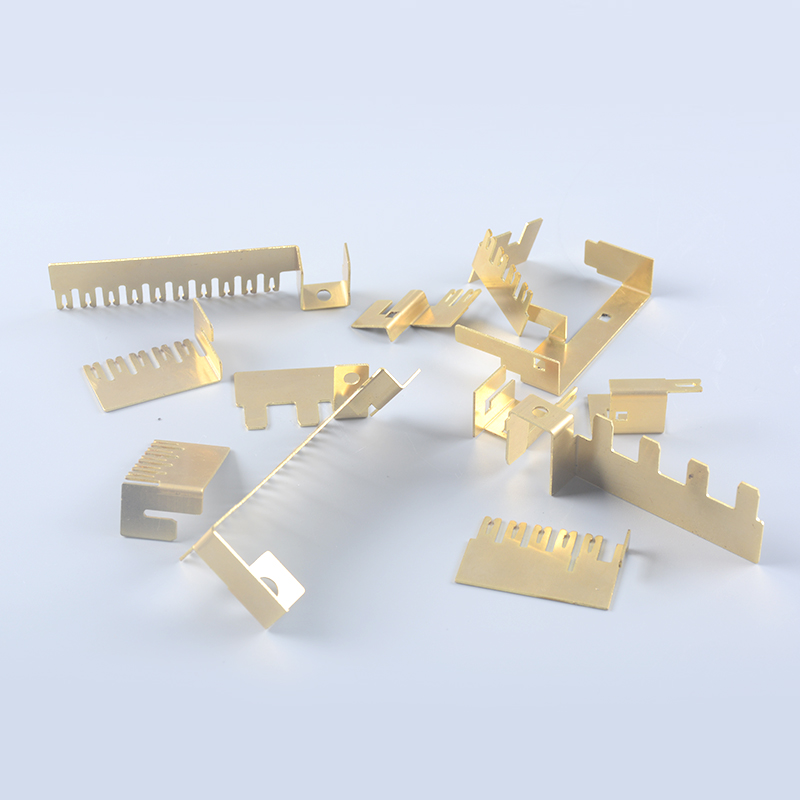

Sheet metal parts have the characteristics of lightweight, high strength, electrical conductivity , low cost, and good mass production performance. They have been widely used in electronic appliances, communications, the automotive industry, medical equipment, and other fields.

PROTO MFG’s plastic injection molding process offers many advantages over other manufacturing processes. From fast and efficient production to the customization opportunities and increased strength and durability of the parts, plastic injection molding offers companies an ideal choice for manufacturing plastic parts.

Sheet Metal: Sheet metal fabrication is used in various industries like construction, automotive, aerospace, and electronics. Sheet metal processes produce parts that possess high strength, stability, and durability making them well-suited for manufacturing of equipment housing or enclosures, wireways, brackets, and chassis components..

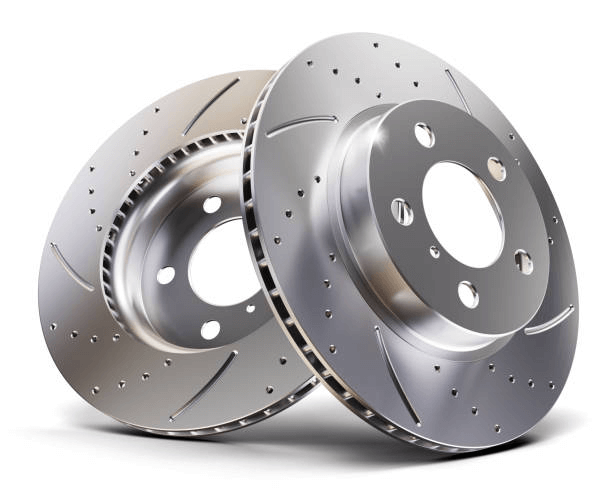

CNC Machining: CNC machining including CNC milling and CNC turning is widely used in industries like aerospace, automobile, medical, energy, and electronics for manufacturing high precision components with tight tolerances. For instance, CNC machining is commonly used to make engine components in the automotive and aerospace industries or medical implants.

Urethane Casting: Urethane casting, due to its versatility, accuracy and relatively quick turnaround, is used in industries like automotive, electronics, aerospace, and medical devices, toys, and props. Urethane cast parts can take various shapes, and also enable designers to make parts that simulate the look, feel, and even weight of a metal component.

Compression Molding: Compression Molding has several unique advantages compared to other molding processes. For instance, it can produce large and intricate parts with minimal waste and cost-effectiveness. PROTO MFG’s compression molding process allows for greater design flexibility and enables the creation of accurate and strong parts. Additionally, compression molding is suitable for manufacturing fiber-reinforced polymer composites, which offer high strength and durability compared to conventional materials.