CNC MACHINING Ι 3D PRINTING MATERIALS

Properties of Nylon

Nylon is a synthetic thermoplastic polymer that has high tensile strength, excellent wear resistance, and good chemical resistance. It can withstand high temperatures and has a low coefficient of friction. Nylon is also lightweight and has excellent electrical insulation properties. Its unique properties make it ideal for several applications.

Industry Applications of Nylon

Nylon is popularly used in the automotive industry, where it is used to make fuel tanks, brake fluid reservoirs, and airbag covers. Its high impact resistance and excellent tensile strength make it ideal for these applications.

In the packaging industry, nylon is used to make films and coatings that provide high barrier properties to retain the freshness of food products. It is also used to make packaging bags for high-end products such as electronics and medical devices.

In the textile industry, nylon is used to make clothes, ropes, and fishing lines. It is also used to make carpets and upholstery fabrics due to its excellent wear resistance and durability.

Parts Applications of Nylon

In mechanical engineering, nylon is used to make gears, bearings, and other parts that require high wear resistance, low friction, and high strength. Nylon parts are also used in electrical and electronic applications due to their excellent electrical insulation properties.

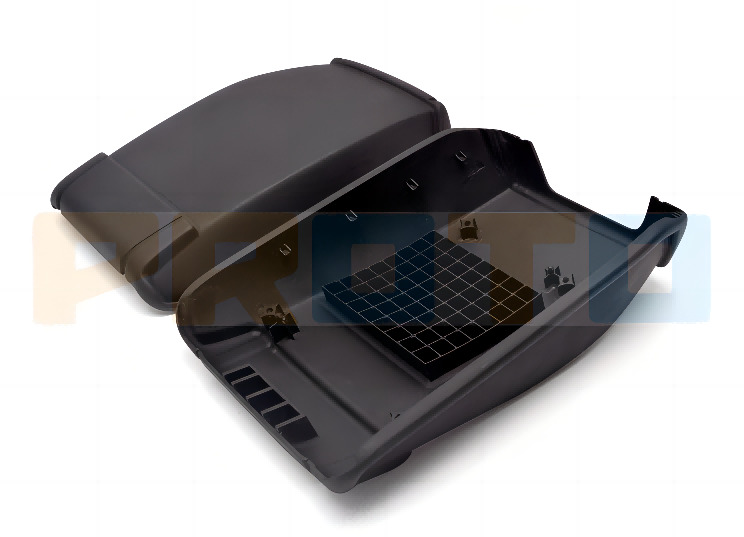

Nylon parts are also used in various consumer goods such as vacuum cleaners, lawn mowers, and power tools. Nylon parts can withstand the high stresses and wear and tear encountered in these applications.

In summary, nylon is an excellent thermoplastic material that offers several properties ideal for numerous applications. Its high tensile strength, excellent wear resistance, and low coefficient of friction make it an ideal material for mechanical engineers, buyers, and designers to consider when developing applications. Its applications are broad, from automotive to packaging, textiles to parts applications. Understanding its properties and the type of applications can provide multiple options to use this material in different industries.