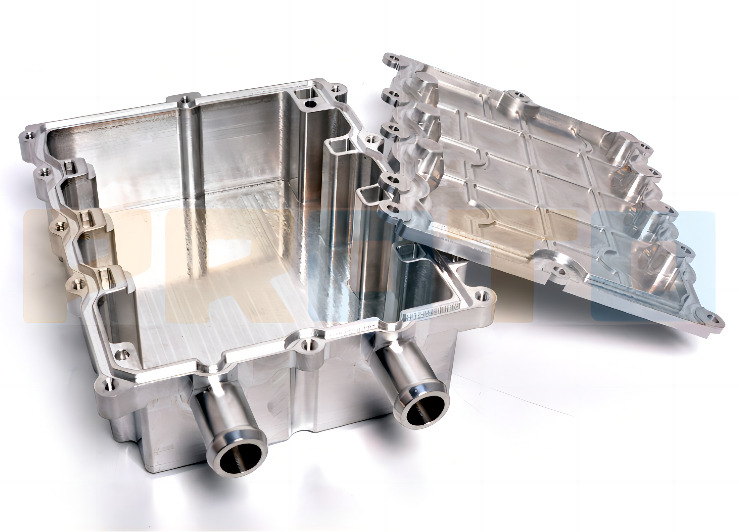

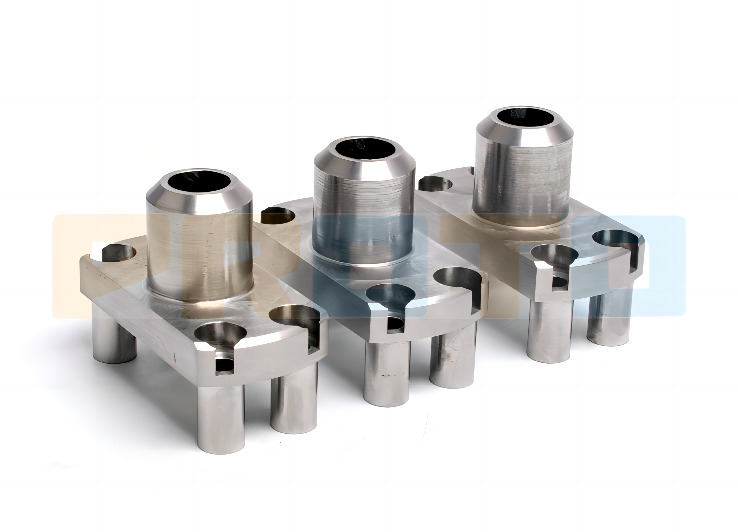

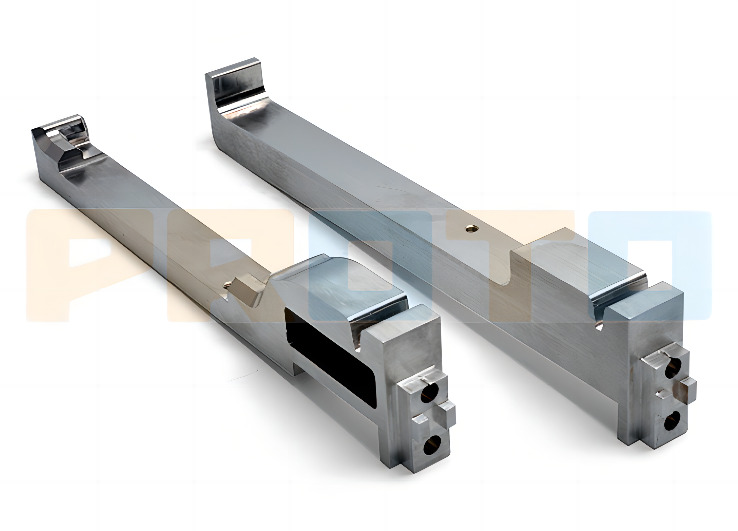

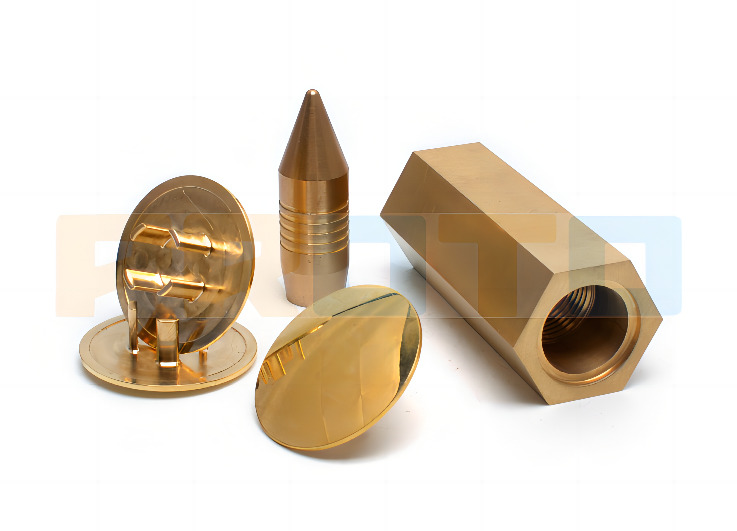

One of the principal advantages of machined parts is the ability to purchase them with no minimum order quantity. For molded parts, it is necessary to fabricate metal tooling — a process that takes a long time and typically costs tens of thousands of dollars. Machining is most commonly used to manufacture metal objects, parts, and tools. Metals that can be machined are stainless steel, aluminum, brass, titanium, and copper. Stainless steel is commonly used for precision machining, offering the advantages of strength and resistance to corrosion. CNC machining operation is used to manufacture plastic and metal prototypes very quickly. They are a very good alternative to 3D printing since machined parts are manufactured using actual material that has properties similar to injection molding material.

PROTO MFG provides high-quality custom precision machined parts and finished machined parts for a range of industries. Our capabilities for CNC metal machining are versatile and we can produce a wide variety of metal parts for various applications. With our state-of-the-art facilities and unique expertise, we can handle high-volume manufacturing and finishing operations. If you need metal parts for your industry, feel free to reach out for an instant CNC machining quote at PROTO MFG.

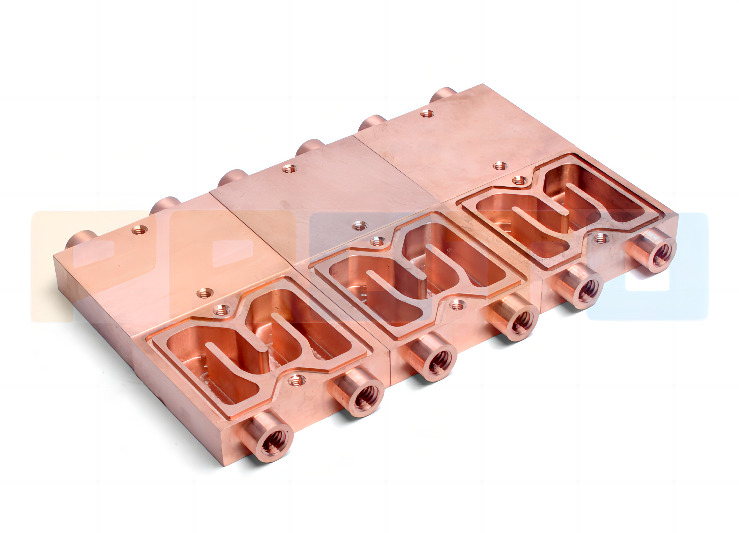

Metal machined parts are widely used in various industries such as automotive, aerospace, medical equipment manufacturing, construction, and many more. These parts are crucial components of various machinery, equipment, and devices. They can be used for manufacturing engine components, transmission systems, bearings, gears, valves, pumps, and much more. Metal machined parts can be made of various materials such as stainless steel, aluminum, brass, titanium, and copper. Each of these materials offers different advantages such as strength, resistance to corrosion, and durability.