![]()

![]()

![]()

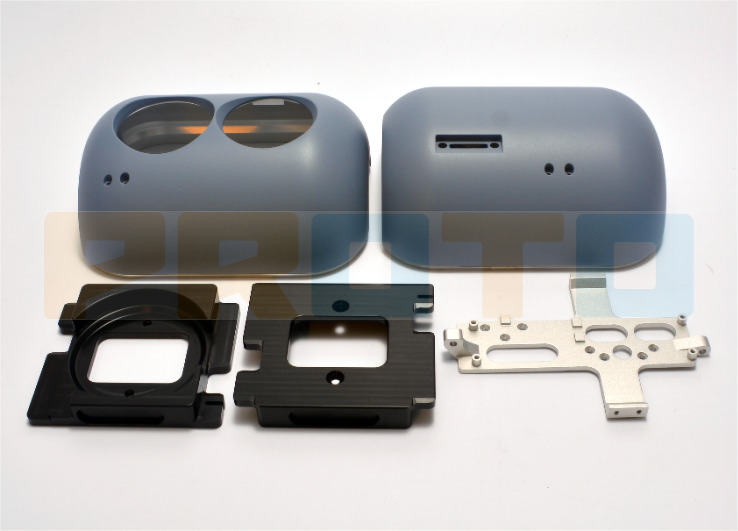

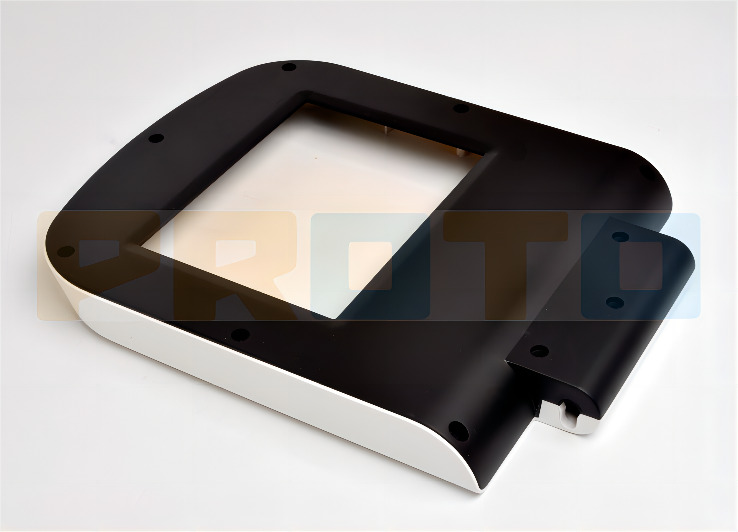

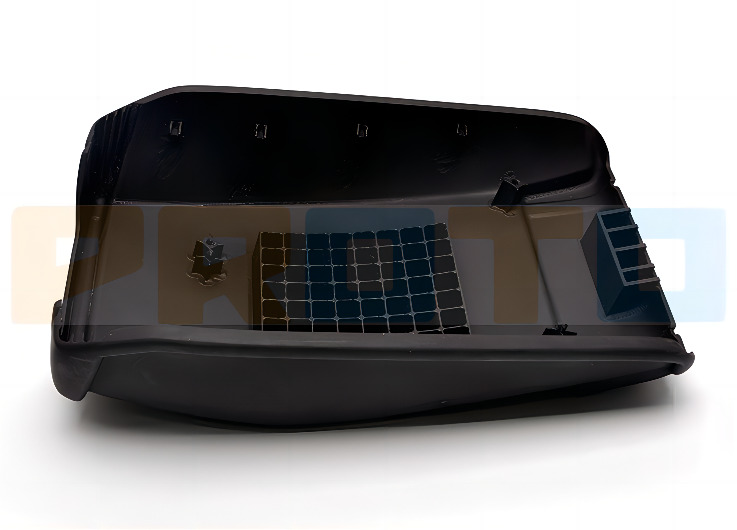

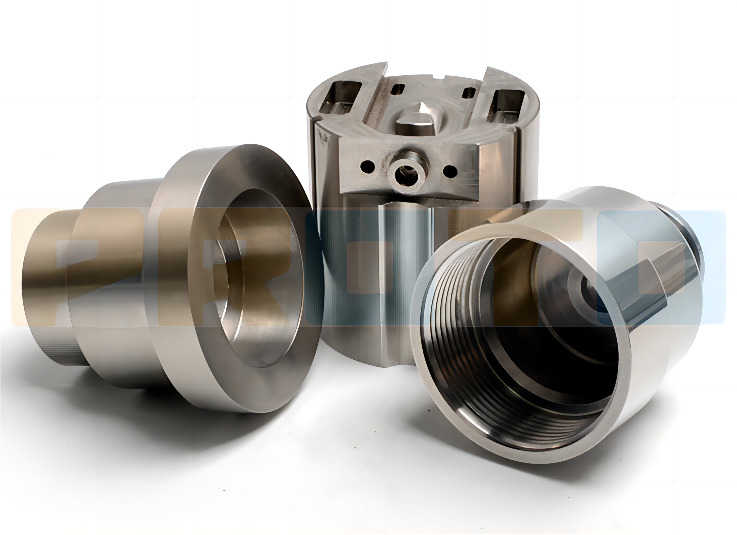

Medical devices require a high degree of precision and accuracy in their components, which is why machined parts are often used in their production. These machined parts can include buttons, switches, levers, monitor housings, and other crucial components. Materials such as stainless steel, aluminum, titanium, and production-grade plastics like PEEK are commonly used for these parts. CNC machining is an ideal method for producing parts for medical devices because it offers unparalleled speed and precision, allowing for the quick and efficient production of high-quality components that meet the strict standards of the medical industry.

Based on the latest report from SmarTech Publishing and Forbes, the medical device industry is expected to experience significant growth in the coming years. According to the report, the use of 3D-printed implants is projected to grow tenfold by 2026, and the medical device market is predicted to reach $410 billion in just a few years. In particular, the demand for CNC-machined medical devices parts like stents, pacemaker components, catheters, drug delivery systems, miniature screws for implants and devices, and ophthalmic devices will continue to grow. These devices require high precision and expertise, which makes them more challenging to manufacture, but also represents a significant market opportunity for medical device manufacturers.