Heat treatment is a manufacturing process that involves heating and cooling metal materials

to alter their physical and mechanical properties, such as hardness, toughness, and ductility.

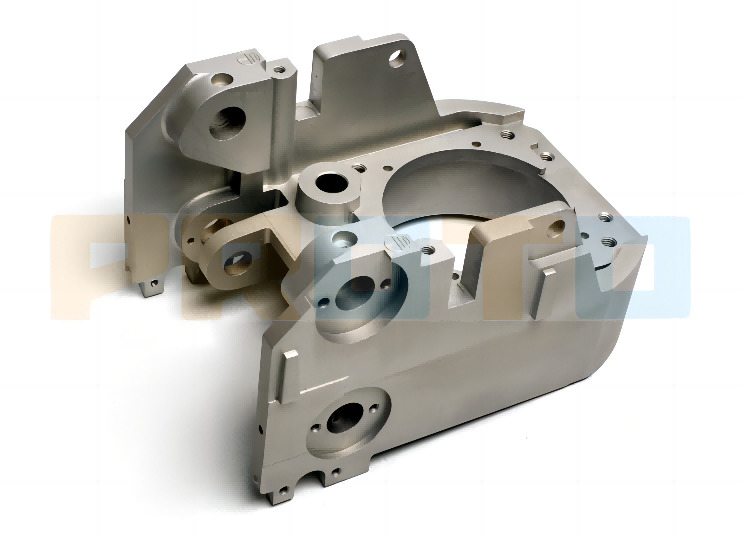

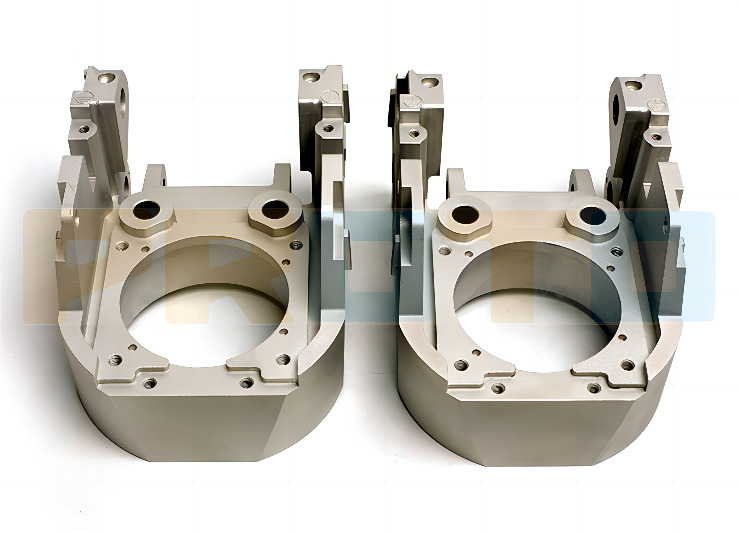

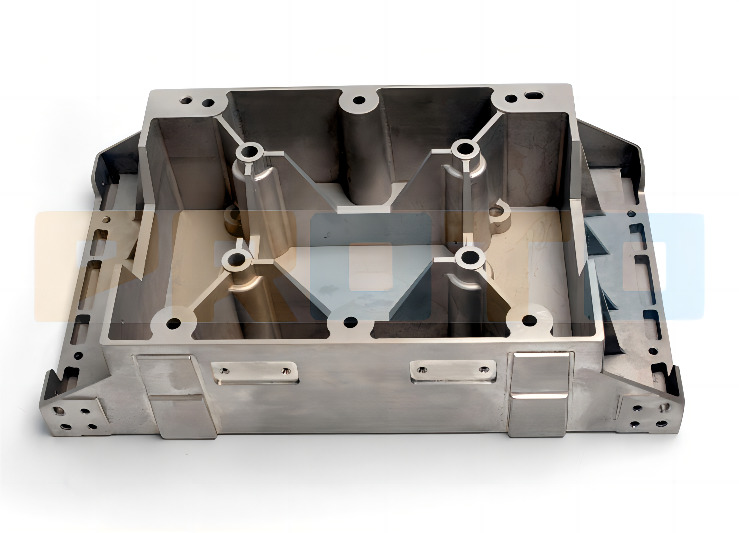

Heat treatment for machined parts refers to the controlled heating and cooling of a material to achieve desired material properties such as hardness, strength, toughness, and ductility.This process is an integral step in CNC machining metal parts as it alters the properties of these parts. Machined parts are typically produced using mechanical CNC technology like a multi-axis lathe, mill, Swiss lathe, or machining center. Because these parts are used in high-precision applications with controlled dimensions, it is important to take extra care in heat treatment to prevent distortion of the components.

There are four basic types of heat treatment that are commonly used: annealing, normalizing, hardening, and tempering. Each type of heat treatment involves heating or cooling a material to achieve a desired effect, such as softening, hardening, or increasing strength and wear properties. Different techniques are used in each process to treat materials, particularly steels.

This can help to improve the performance and lifespan of various components, such as those used in the automotive, aerospace, and construction industries.