Anodized aluminum stands as a testament to the marriage of aesthetics and functionality in modern industrial design. One of its most captivating aspects is the spectrum of colors it can boast, transforming this versatile material into a canvas of hues. In this exploration, we delve into the vibrant world of anodized aluminum colors, unraveling the intricacies of the anodizing process and the significance of color in this unique material.

What is Anodizing Process?

Anodizing is a sophisticated electrochemical process that enhances the properties of aluminum, making it more resilient and versatile. The process involves immersing the aluminum in an electrolytic bath and passing an electric current through it. This bath typically contains sulfuric acid or other acidic solutions. The aluminum acts as the anode in this electrolytic cell.

During anodization, the aluminum undergoes controlled oxidation. As the electric current passes through the aluminum, oxygen ions are released at the surface of the metal. These ions combine with the aluminum to form aluminum oxide, creating a protective layer on the surface of the material. This oxide layer is not only highly durable but also porous, providing an ideal surface for color integration.

The thickness of the oxide layer is a critical factor in the anodizing process. It can be controlled by adjusting the voltage applied during anodization. The higher the voltage, the thicker the oxide layer, which in turn influences the final appearance and color of the anodized aluminum. This controlled oxidation gives anodized aluminum its unique set of properties, including increased corrosion resistance and improved hardness.

What is the Role of Color in Anodized Aluminum?

The incorporation of color in anodized aluminum is not merely a superficial addition; it is an integral part of the material itself. The porous nature of the oxide layer allows for the absorption of dyes or pigments, creating a spectrum of colors that are not only vibrant but also resistant to fading or peeling.

The role of color in anodized aluminum goes beyond aesthetics. Different applications demand various colors for functional or branding purposes. For instance, in the architectural industry, anodized aluminum is often used for building facades, where color is crucial for achieving specific design aesthetics. In consumer electronics, anodized aluminum colors not only serve design preferences but also aid in product differentiation and brand recognition.

Furthermore, the color in anodized aluminum is not susceptible to typical wear and tear. Unlike painted or coated surfaces that can chip or peel over time, the color in anodized aluminum is an integral part of the material, making it more durable and resistant to external elements. This makes anodized aluminum a preferred choice in applications where long-lasting and vibrant colors are essential.

Why There are different colors of anodized aluminum? Factors Influencing the Color of Anodized Aluminum

The vibrant array of colors exhibited by anodized aluminum is a result of a meticulously controlled process that allows for a spectrum ranging from subtle tones to bold hues. Several key factors influence the coloration of anodized aluminum, making it a versatile material for a variety of applications.

The type of aluminum alloy used significantly impacts the final color of anodized aluminum. Different alloys contain varying amounts of alloying elements, such as copper or silicon, which influence the thickness and structure of the oxide layer formed during anodization. These variations in the oxide layer contribute to the diverse colors that can be achieved, allowing designers and manufacturers to tailor the appearance of the material to suit specific needs.

The surface finish of the aluminum before anodization plays a crucial role in determining the final color. Factors such as the smoothness, roughness, or texture of the surface can affect how light interacts with the oxide layer. A polished surface, for example, may produce a different color than a matte finish, providing additional customization options for achieving desired aesthetics.

The voltage applied during the anodizing process directly influences the thickness of the oxide layer. Higher voltages result in a thicker layer, altering the way light is absorbed and reflected by the aluminum. This voltage-controlled thickness is a key factor in the color spectrum of anodized aluminum, enabling precise control over the final appearance. Designers can experiment with different voltage levels to achieve specific colors, adding a layer of customization to the process.

The composition of the electrolyte bath, in which the aluminum is immersed during anodization, plays a vital role in color development. Sulfuric acid is commonly used, but variations in the concentration of the acid or the inclusion of other additives can affect the final color. The chemical composition of the electrolyte bath interacts with the aluminum surface, influencing the growth of the oxide layer and, consequently, the color produced.

The thickness of the oxide layer formed during anodization is a critical factor in color development. Thin oxide layers may produce transparent or lightly colored finishes, while thicker layers can result in more vibrant and saturated hues. Control over the thickness is achieved through precise regulation of the anodizing parameters, providing the flexibility to produce a wide range of colors.

After anodization, some manufacturers may opt for additional processes to further enhance or modify the color of the aluminum. These post-treatment processes may include sealing, dying, or other chemical treatments that can add depth, luster, or additional protective layers to the anodized surface.

To briefly understand the diverse colors of anodized aluminum, we can find the answer from the different types of anodizing:

Type I (Chromic Acid Anodizing): Generally does not produce vibrant colors; it often results in a thin, clear, or yellowish film.

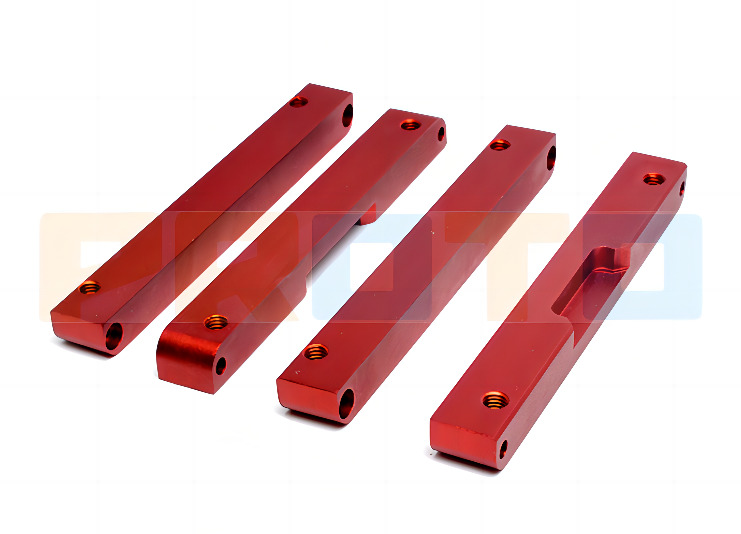

Type II (Sulfuric Acid Anodizing): Can produce a range of colors, including gold, brown, red, blue, and black, depending on the thickness of the anodized layer. The colors are a result of light interference with the oxide layer. The example product such as our blue and red anodized aluminum knobs.

Type III (Hard Anodizing): Similar color range to Type II but tends to produce darker and more subdued colors due to the thicker and denser oxide layer.

In conclusion, the diverse colors of anodized aluminum are not arbitrary but a result of a combination of factors. By carefully manipulating alloy composition, surface finish, voltage during anodization, electrolyte bath composition, and post-treatment processes, manufacturers can achieve a rich spectrum of colors, providing endless possibilities for designers.

How to Achieve Consistent and Predictable Colors in Anodized Aluminum?

Consistency in color is crucial, especially in industries where uniformity is paramount. Achieving consistent and predictable colors in anodized aluminum involves meticulous control of the anodizing parameters. Tight regulations on temperature, concentration of the electrolyte bath, and duration of the process are essential to ensure that every batch exhibits the desired color profile. Cutting-edge technology and quality control measures further contribute to the precision of color reproduction, offering manufacturers and designers the assurance of a reliable palette.

Conclusion

In the realm of industrial design and architecture, anodized aluminum emerges as a versatile and aesthetically pleasing choice. The ability to infuse a spectrum of colors into its very structure elevates its appeal. From the elegant sheen of champagne to the bold statement of deep bronze, anodized aluminum colors are not just an embellishment but a testament to the marriage of art and engineering. As technology continues to advance, unlocking new possibilities for color manipulation, the vibrant world of anodized aluminum is poised to captivate the imagination of designers, architects, and consumers alike, adding a splash of brilliance to the material that has become an icon of modern design.