Electrical Discharge Machining (EDM) is a nonconventional machining process used primarily for tasks that would be unachievable with conventional methods. It uses electricity to erode the surface of conductive materials. Since no tool physically contacts the workpiece,EDM can maintain fine surface finishes even on intricate and delicate parts.The technique is broken down into die, wire, and drilling subtypes. EDM can be used to create turbine and compressor discs, hip and knee implants, pacemakers, die molds, and microelectronics.

This article will discuss EDM, how it works, its types, and its real-world applications.

What Is Electrical Discharge Machining?

Electrical Discharge Machining, also referred to as spark machining, is an alternative to traditional machining that uses thermal rather than mechanical forces to remove material. Specifically, a hot electrical spark is what removes material from the workpiece. EDM only works on materials that are electrically conductive such as brass, aluminum, and steel.

The erosive properties of electricity were discovered in 1770 by Joseph Priestly. However, EDM was not invented until 1943 when two soviet scientists, B. Lazarenko and N. Lazarenko, used electricity to machine conductive materials.

How Does Electrical Discharge Machining Work?

EDM works by using a soft electrode — commonly graphite — to generate a spark between the electrode and the target area. It causes a portion of the machined part to vaporize. The temperature of the sparks ranges between 14,500 and 21,500 ºF. The melted and vaporized particles of metal are carried away from the machined area by a dielectric fluid such as oil.

This common principle is applied to all three types of EDM: die-sinking EDM, wire EDM, and hole-drilling EDM. In die EDM, the electrode is pre-formed in the shape of the desired cut and employed to cut that specific geometry. The same principles apply to wire EDM, but the wire electrode acts in the same way as a wire cheese cutter. In hole-drilling EDM, a pulsing electrode is used to create small and deep holes with no burrs.

Most conductive materials can be machined using the EDM process. Among the few exceptions to this rule are the high-grade nickel alloys which are often used in aerospace. However, specialized electrode materials and carefully selected machining speeds can sometimes allow nickel alloys to be machined this way.

What Is the Principle of Electrical Discharge Machining (EDM)?

EDM works on the principles of thermal erosion and vaporization. By sparking electricity from the electrode to the machining surface, EDM devices are able to erode and vaporize metal which is then removed from the area using a dielectric fluid.

What Are the Key Components and Tools Involved in Electrical Discharge Machining?

The key components and tools involved in EDM are listed below:

Electrodes: Electrodes come in the form of wires, dies, or tubes.

Guides: Referred to as ferrules, these are made of ceramic and used to guide the electrode to the workpiece.

Dielectric Fluid: Fluids cool the electrode and workpiece and circulate eroded metal away from the machined area.

Current Supply: The electrode must be supplied with enough electricity to spark and erode the metal.

What Are Different Types of EDM?

There are three types of EDM, as listed below. Each one uses different tools to perform cutting operations.

1.Die-sinking EDM (also known as conventional EDM, cavity-type EDM, or ram EDM)

2.Wire-cutting EDM

3.Hole-drilling EDM

What Are the Primary Applications of Electrical Discharge Machining in Industry?

EDM is used to achieve things that conventional machining either can’t match in terms of quality or can’t achieve at all. Some of the applications of EDM are:

1.Drilling small holes.

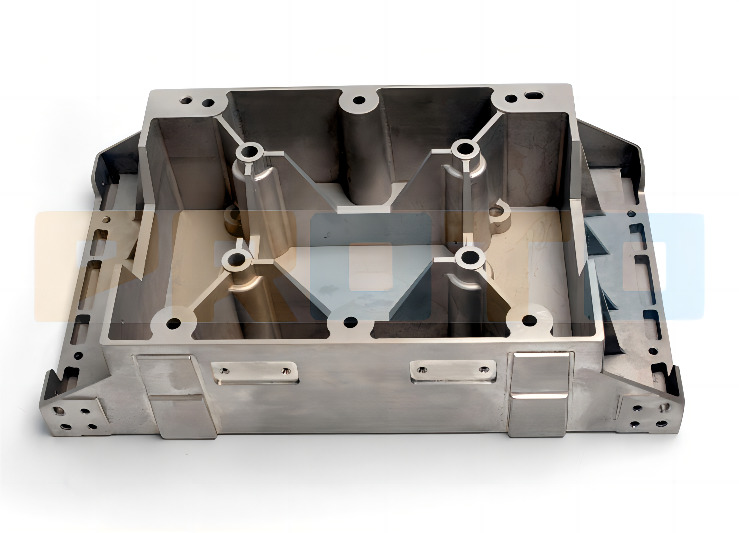

2.Mold and die production.

3.Removal of broken tools in workpieces.

4.Creating burr-free medical equipment.

5.Producing turbine discs for aerospace applications.

What Surface Finish Is Achieved With Electrical Discharge Machining?

Unlike conventional machining, EDM does not leave any marks in the direction of cutting. EDM can achieve a very high-quality surface finish, so that’s one of the main reasons to choose it over other machining methods. The surface finish will also depend on the speed of the machining process; the slower the machining the better the surface finish. However, slower movement also raises the cost.

How Does EDM Cutting Compare to Laser Cutting?

Laser cutting and EDM are typically used for different tasks. Laser cutters can only cut a limited thickness whereas EDM is restricted only by the size of the machine. Laser cutting is not as precise as wire EDM. The advantage of laser cutting is that it is not limited to conductive materials, while EDM is.

Is EDM Accurate?

Yes, EDM is highly accurate. The specific accuracy, however, will depend on a few factors, including: the electrode used, the material being cut, the speed of cutting, and the current input. Generally, EDM can achieve a dimensional tolerance of +/- 0.0002”.

What Are the Advantages of Using EDM for Material Removal?

There are many advantages to be found in the EDM process. EDM is usually used to machine parts that can’t be made with conventional machining. Some of the advantages of EDM are:

1.It can cut complex shapes, very deep holes, and undercuts which cannot be machined with other conventional machining methods. EDM has the added advantage of not creating burrs.

2.The process is not affected by the hardness of the material and will cut through hard metals just as easily as soft metals.

3.No marks get left behind unless the EDM is carried out too fast and the surface is left with a “blasted” texture.

4.The precision can easily be fine-tuned. Tolerances of +/- 0.0002” are typically possible.

5.Since there is no contact between the electrode and the workpiece, it imparts little to no force during machining. This allows very thin and delicate parts to be machined.

What Are the Disadvantages of Using EDM for Material Removal?

Despite the wonders of EDM, there are also disadvantages to be aware of, such as:

1.The machines cannot remove large amounts of material quickly, which slows the whole machining process. It’s hard to achieve high throughput with EDM.

2.This is an energy-intensive process, which is not good for a company’s carbon footprint. Unless electricity can be sourced in a sustainable way, some organizations will be required to find an alternative to EDM.

3.The time and electricity demands translate into expensive operating costs.

4.The process is limited to conductive materials only. Even some conductive materials like high-grade nickel alloys are hard to machine this way.

When To Use EDM?

EDM is only used for parts whose designs demand tight tolerances, good surface finishes, undercuts, or other complex machining features. Some examples of where EDM is used include: cutting extrusions, rotary forms, or sharp internal corners, drilling micro holes or curved holes, engraving hard materials, or removing broken tools or fasteners from workpieces.

How Does EDM Differ From Traditional Machining Processes?

The main difference in principle between EDM and traditional machining is that EDM doesn’t make contact with the workpiece, but instead uses electrical sparking to remove material. This gives the resulting part a better surface finish with impressive dimensional tolerances. It can also allow for otherwise impossible undercuts. Traditional machining processes, however, are cheaper and faster. One exception to this is grinding, which takes longer to remove material than EDM.

What Types of Materials Can Be Machined Using Electrical Discharge Machining?

EDM can be used to machine virtually any conductive material without too many challenges. EDM does not work with non-conductive materials like glass, ceramics, plastics, wood, or composites. The workpiece material itself acts as part of the spark’s circuit, so it must conduct electricity. Materials that can be EDM machined include:

1.Brass

2.Aluminum

3.Steel

4.Copper

5.Nickel

6.Tungsten

What Are the Safety Considerations When Operating EDM Equipment?

The main risks when operating EDM machines come from electricity. Not only is it dangerous to be close to the electrode due to the risk of electric shock, but all metal parts must be properly grounded to protect against electrocution. The circulation of dielectric fluid also needs to be monitored during EDM operation. Without it, EDM can create flammable gasses which pose a fire risk and are harmful to inhale.

Are There Different Variations or Techniques Within Electrical Discharge Machining?

Yes, there are three main variations of EDM: die sinking, wire cutting, and hole drilling. All run on the same basic principles, using a sparking electrode to remove material. Die sinking uses a die tool electrode to impart its geometry onto a workpiece. Wire cutting, on the other hand, uses a continuously fed wire electrode to cut a workpiece in much the same way a cheese slicer cuts cheese. Hole drilling EDM uses rods to drill very shallow, very deep, and/or very narrow holes.

What Are the Challenges Associated With EDM Technology?

There are a number of challenges facing EDM technology. A few of the most significant ones are listed below:

1.As a machining process, EDM uses a large amount of electrical energy. With the push to reduce carbon footprints, industries will try to find other machining methods if energy consumption cannot be reduced.

2.The complexity of the machining process means the talent pool of technicians able to successfully carry out EDM operations is small. It may be hard to attract and retain experts.

3.EDM units are often limited in the size of the parts they can work on. While they are perfect for small and intricate parts, they are not so accommodating for large work pieces.

How Does the Choice of Electrode Material Affect the EDM Process?

The varied properties of different electrode materials bring with them their own pros and cons. Brass, for example, causes faster material erosion than copper and tungsten and can be easily machined or extruded. This is why brass is used as an electrode material in wire EDM where the wire is fed continuously during the process. While copper is more wear-resistant than brass, it is also harder to machine. Copper is also a great conductor and so is used for applications which require a fine finish. It is also used in conjunction with tungsten to make copper tungsten electrodes which, although expensive, are very effective at machining where there is poor dielectric circulation, or in the machining of tungsten carbide.

What Is the Role of Dielectric Fluid in Electrical Discharge Machining?

The dielectric fluid performs two functions during EDM operation. One is to cool the electrode and the machining site to prevent overheating. The sparks generate temperatures of 14,500-21,500 ℉. Another function is to flush the melted/eroded metal from the machining site and allow the material below to be machined.

What Are Some Common Problems in EDM?

There are a range of challenges that EDM machinists can face. One common problem is electrode wear. If an electrode tapers due to wear, the altered dimensions will be reflected in the machined surface. The distribution of electrode discharge can also be problematic. Sparks recurring in the same place can cause unequal material removal, so manufacturers need to use a discharge pulse control technology to control the distribution of electrical charge. Contaminated dielectric fluid can also attract a higher number of sparks in localized areas, so fluid must be continuously circulated.

What Are Real-World Examples of Products Manufactured Using EDM?

Examples of the industries that use EDM and the parts they create are listed below:

1.The medical industry uses EDM to create implant devices including pacemakers, cochlear implants, and neurostimulators. EDM has also been used on hip implants, spinal fixtures, and dental implants like: crowns, bridges, and abutments.

2.In the aeronautical industry, EDM is used to machine high-grade nickel alloys for use in turbine discs, compressor discs, and stator vanes.

3.The manufacturing industry uses EDM to produce plastic die molds and extrusion dies and to perform die sinking.

Is EDM a Nonconventional Machining Technique?

Yes, EDM is considered a nonconventional machining technique.Machines that make direct contact with the workpiece are defined as conventional and machines that do not make contact are nonconventional. Conventional techniques include milling, turning, boring, honing, and grinding. Other non-conventional techniques include chemical machining, laser beam machining, water jet cutting, and ultrasonic machining.

Does EDM Work With Inconel®?

Yes, Inconel® can be machined with EDM. Conventional machining processes are not as effective because Inconel® is so hard, thermally conductive, and prone to work-hardening. Since EDM doesn’t make contact with the workpiece, these properties aren’t an issue.

What Is the Difference Between EDM and Centerless Grinding?

EDM and centerless grinding processes differ significantly. To start, EDM is a contactless process, meaning there are no physical forces imparted on the workpiece, and neither are there any directional marks left after machining. Centerless grinders do make contact with the part and leaves directional marks on the surface of the material. However, centerless grinding can produce such a high-quality finish that the directional marks are unnoticeable. Speed is another distinct factor, EDM is a faster process than grinding. Additionally, only EDM can achieve particularly intricate details, drill deep holes, and create undercuts.

Summary

This article presented electrical discharge machinin, explained it,and discussed its types and various applications. To learn more about electrical discharge machining, contact a Proto MFG representative.

Proto MFG provides a wide range of manufacturing capabilities,including machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free,no-obligation quote.