Anodizing is an electrochemical process that deposits an oxide layer on a metallic surface to provide corrosion protection — and anodized coatings may be dyed in various colors. Hard anodizing, when compared to regular anodizing, creates a thicker, more durable, and wear-resistant aluminum oxide layer. Hard anodizing is also known as “Type III anodizing” per specification MIL-A-8625 or “hard coat anodizing.” This CNC finishing process is typically used on aluminum and titanium alloys (alkaline anodizing) to improve their corrosion resistance, hardness, and overall durability.

Hard Anodizing Colors – Overview

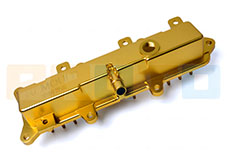

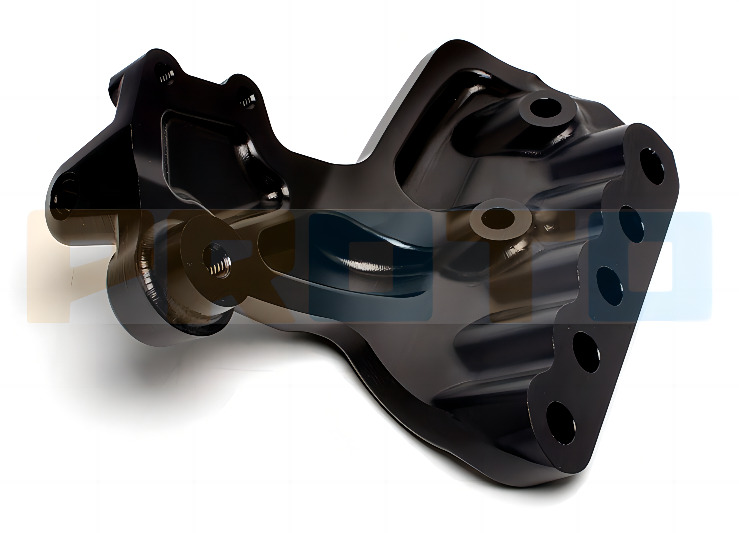

The colors achieved through hard anodizing vary depending on several factors, including the type of metal being anodized, the anodizing process parameters, and the dye used. Some common colors achieved through hard anodizing include black, red, blue, green, and gold.

In addition to the aesthetic benefits of hard anodizing colors, the process also provides added protection to the metal surface. The dye used in the anodizing process is absorbed into the pores of the oxide layer, creating a thicker, more durable, less porous layer less susceptible to wear and corrosion.

Hard anodizing colors have many applications and benefits, including:

Hard Anodizing Colors – Common Applications

Some examples of products where hard anodizing colors are commonly used include:

Aerospace components, such as aircraft parts and components

Automotive components, such as engine parts and wheels

Consumer goods, such as sporting equipment and jewelry

Medical devices, such as surgical instruments and implants

Hard anodizing colors provide a range of benefits and can be used in a variety of applications. The specific colors and finishes that can be achieved will depend on several factors, including the metal being anodized, the anodizing process used, and the dye or pigment used in the process.

Some examples of products where hard anodizing colors are commonly used include:

Aerospace components, such as aircraft parts and components

Automotive components, such as engine parts and wheels

Consumer goods, such as sporting equipment and jewelry

Medical devices, such as surgical instruments and implants

Hard anodizing colors provide a range of benefits and can be used in a variety of applications. The specific colors and finishes that can be achieved will depend on several factors, including the metal being anodized, the anodizing process used, and the dye or pigment used in the process.

Hard Anodizing Colors – Our Best Tips

Any chemical conversion process introduces additional complexity. It takes significant knowledge to specify hard anodizing for your parts. It’s even more complex to understand the process and perform it. But fear not! PROTO MFG has you covered.

Here are some essential tips regarding hard anodizing colors.

Processing Tips:

The anodizing process itself is non-conductive. More specifically, the oxide layer formed is non-conductive and highly insulating. Therefore, to color the anodized layer, dyes must be utilized. These dyes themselves may be conductive or non-conductive.

The process of hard anodizing involves immersing the metal in an electrolytic solution and applying an electric current to it. This creates a layer of oxide on the surface of the metal, which is then filled with dye or pigment to create the desired color.

Hard anodizing can be combined with other processes, such as laser etching or silk-screen printing, to create designs or labels on the anodized surface.

The color of the anodized coating can be affected by several processing factors, including:

Type of metal: Different metals, such as aluminum alloys, may produce different colors when anodized.

Anodizing process parameters: The color of the anodized coating can be affected by the type of electrolyte solution used, the voltage applied, the duration of the anodizing process, and the temperature of the solution.

Dyeing process: Anodized coatings can be dyed to produce various colors. The dyeing process involves immersing the anodized part in a dye bath, where the dye is absorbed into the porous oxide layer.

Surface finish: The surface finish of the metal can affect the appearance of the anodized coating. A polished surface will produce a brighter, more reflective finish than a matte finish.

Thickness of the anodized coating: The thickness of the anodized coating can affect the color of the coating. Thicker coatings may produce a darker or more vibrant color.

Lighting conditions: The color of the anodized coating may appear differently under various lighting conditions, such as natural compared to artificial light.

Environmental factors: Exposure to sunlight, temperature, and humidity can affect the color and durability of the anodized coating over time.

Hard Anodizing Color Properties & Considerations:

Thicker coatings generally produce darker colors. The thickness of the anodized layer determines the depth or intensity of color achieved. The thickness of the oxide layer created through hard anodizing can also be controlled to achieve different levels of hardness and corrosion resistance. This can be useful in applications where durability is important.

Hard anodizing produces a range of colors, including black, gold, blue, red, and green.

The specific shade of the color can vary depending on the alloy used and the process parameters, such as the current density, temperature, and time.

The color of the anodized layer can fade or change over time, especially when exposed to UV light or harsh environments.

Hard anodizing is not suitable for achieving exact color matching, and there may be variations in color between different batches.

Hard anodizing colors are durable and long-lasting. The dye or pigment is absorbed into the pores of the oxide layer, creating a color integrated into the metal itself. This makes it more resistant to wear, scratches, and fading than surface coatings or paints.

Hard anodizing colors can be customized to achieve specific shades and finishes, depending on the needs of the application. Common colors achieved through hard anodizing include black, red, blue, green, and gold.

Hard anodizing colors can improve the electrical conductivity or insulation of the metal surface. This can be useful in electrical and electronic applications where conductivity or insulation is important.

Hard anodizing colors offer a range of benefits, including improved durability, corrosion resistance, and aesthetic appeal. The specific benefits and colors achieved will depend on several factors, but hard anodizing colors can be a valuable solution for many applications.

What are the Standard Hard Anodizing Colors?

Several standard anodizing colors are commonly used in industrial applications. The exact shades of these colors may vary depending on the specific alloy being anodized and the process parameters used. Still, the following colors are commonly achieved through anodizing:

It’s important to remember that the appearance of these standard anodizing colors can vary depending on the specific dye used and the thickness of the anodized layer. Additionally, custom colors can be achieved through anodizing, including purple, pink, and bronze.

How Long Does Anodized Color Last?

The durability of anodized color depends on various factors, such as the thickness of the anodized layer, the specific alloy being anodized, and the conditions the anodized part is exposed to. With proper care and maintenance, anodized color can last many years – or even decades.

Anodized surfaces are highly resistant to corrosion and wear, and the anodized layer itself provides a barrier against further oxidation. Because the color is embedded within the anodized layer, rather than simply being a surface coating, it is less prone to chipping, flaking, or peeling.

However, it’s important to note that anodized color can be affected by exposure to UV light, high temperatures, and certain chemicals. In outdoor applications, for example, the color may fade or shift over time due to exposure to sunlight. Additionally, harsh chemicals or abrasives can damage the anodized layer and cause the color to deteriorate.

To ensure the longest lifespan for anodized color, it’s important to avoid exposing anodized parts to these harsh conditions and to clean them regularly with a mild detergent and a soft cloth. Additionally, it’s important to consult with an experienced anodizing provider, like Fictiv, who can advise on the best anodizing process and color options for your specific application.

What are the Steps to Hard Anodizing Colors?

The steps involved in hard anodizing colors are similar to those for standard hard anodizing. Here’s an overview of the process:

Preparation: The aluminum part to be anodized is cleaned to remove any dirt, grease, or other contaminants that could interfere with the anodizing process. This typically involves a combination of mechanical cleaning, such as sandblasting or polishing, and chemical cleaning, such as an alkaline or acid bath.

Anodizing: The cleaned part is then immersed in an electrolytic bath containing an acid solution, such as sulfuric acid. An electric current is passed through the solution, which causes a controlled oxidation reaction on the aluminum’s surface. This creates a thick, durable, anodized layer with the desired color and corrosion resistance.

Dyeing: Once the anodized layer has been formed, the part is rinsed and immersed in a dye solution bath. The dye is absorbed into the porous anodized layer, creating the desired color.

Sealing: After dyeing, the part is again rinsed and immersed in a sealing solution, typically an organic polymer or nickel acetate. This helps to close the pores in the anodized layer, which improves the corrosion resistance and durability of the coating. Sealing can also help to improve the color fastness of the anodized layer.

Quality control: Upon completion of the anodizing process, the part is inspected for quality and compliance with the desired specifications. This may involve measuring the thickness of the anodized layer, checking the color and appearance of the part, and performing other tests required.

Tips for Masking and Plugging Parts Before Hard Anodizing

For parts with threads and holes or intricate designs with complex assemblies, masking and plugging prevents anodization buildup that may negatively impact the function of those features, especially if you require tight tolerances.

Masking can be used for aesthetic purposes, such as different colored areas, or to protect or promote certain physical or electrical properties, such as electrical conductivity in specific areas. Depending on the part complexity and masking design, masking and plugging can actually reduce the costs in the anodizing process because you may not need your entire part anodized.

How to Communicate Masking Requirements

While there is no single method that all design engineers must use to call out masking and plugging requirements, traditionally, communicating masking or plugging requirements involved

Callouts on 2D drawings for the finishing type that includes notes or flag notes for surfaces to be finished or to be masked

Masking and plugging legends on drawings. Basically, a table that shows what the masking or plugging requirements are for each part in an assembly.

Highlighted or color-coded drawings with masking one color and non-masked areas another color.

Complex masking drawings which accompanying the part drawings, to show the dimensions of masked areas and are often associated with notes or instructions for masking.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.