Without access to advanced manufacturing equipment and computer programming, civilization as we know it would not exist. Would we have nice things? Sure. But would we have traveled to the moon and outer space and explored the deep depths of the ocean? Likely not at the scale we are able to today. We have CNC machines to thank for many of the advancements around us that make our lives easier and more enjoyable. CNC (computer numerical control) machines have revolutionized manufacturing processes across various industries. CNC routers and CNC mills are the two most commonly used CNC machines. While both are capable of automated precision machining, they have distinct differences that make them suitable for specific applications.

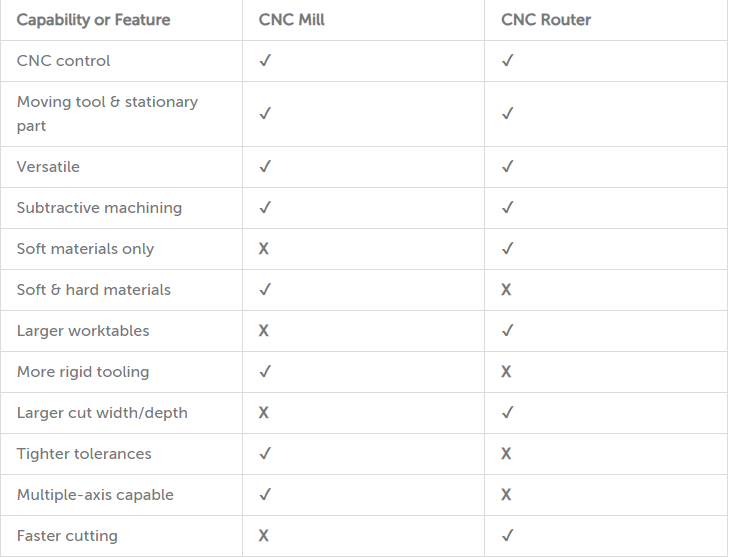

CNC routers are versatile, subtractive machines primarily used for cutting, shaping, and engraving wood, metals, plastic, and composites. They utilize a rotating cutting tool (usually a router bit) to remove material from the stationary workpiece. CNC mills, also known as CNC machining centers, are designed for precise cutting, tight tolerances, complex geometries, drilling, and shaping of solid, harder materials like metal, plastic, and composites. They employ rotating cutting tools, such as end mills or drills, to remove material from the workpiece.