Welding is an essential process in various industries, allowing for the joining of materials to create structures, machinery, and more. There are different types of welding processes, each with its own unique characteristics and applications. In this article, we will explore the four main types of welding – MIG, TIG, stick, and flux-cored – and delve into the advantages, disadvantages, and uses of each.

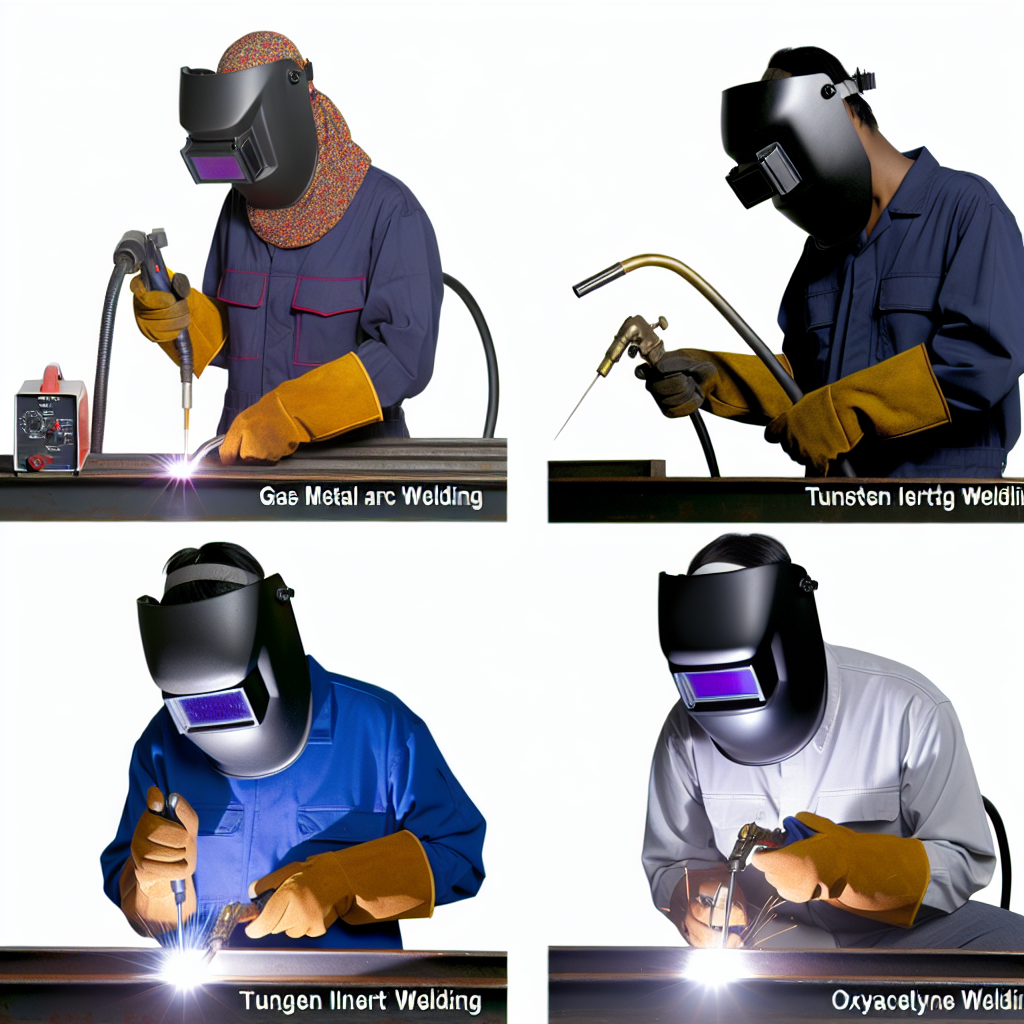

MIG welding, also known as Gas Metal Arc Welding (GMAW), involves using a wire electrode that is fed through a welding gun. The electrode melts and fuses together with the base materials, creating a strong bond. One of the significant advantages of MIG welding is its speed and efficiency, making it ideal for high-volume production. However, it may not be suitable for outdoor welding due to its sensitivity to wind. MIG welding is commonly used in industries such as automotive, manufacturing, and construction for its versatility and ability to weld various metals.

TIG Welding TIG welding, or Gas Tungsten Arc Welding (GTAW), uses a non-consumable tungsten electrode to create the weld. This process allows for precise control over the heat input, making it suitable for welding thin materials and intricate designs. TIG welding produces high-quality, clean welds but is slower compared to other methods. It is preferred in industries like aerospace and automotive, where precision and aesthetics are crucial.

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the oldest and most straightforward welding processes. It involves using a flux-coated electrode that melts and shields the weld from contamination. Stick welding is versatile and can be used in various positions, making it suitable for field repair and fabrication work. However, it requires more skill and produces slag that needs to be removed after welding. Stick welding is commonly used in construction, pipelines, and structural fabrication.

Flux-cored welding is similar to MIG welding but uses a tubular wire filled with flux instead of a solid wire electrode. This process allows for higher deposition rates and deeper penetration, making it suitable for heavy-duty applications in industries like shipbuilding and structural steel. Flux-cored welding is more forgiving of dirty or rusty materials compared to other methods but can produce more smoke and fumes.

When choosing a welding process for a project, several factors need to be considered, such as the material type, thickness, and welding environment. MIG welding is best for high-speed production, TIG welding for precision and clean welds, stick welding for versatility and field work, and flux-cored welding for heavy-duty applications. Each type has its strengths and weaknesses, so it is essential to evaluate which method suits the project requirements best.

To select the right welding process, consider factors like material thickness, joint type, and desired weld quality. Match the welding method to the project needs, whether it requires speed, accuracy, or versatility. Consulting with welding professionals can provide valuable insights and recommendations based on experience and expertise.

In conclusion, understanding the different types of welding processes is crucial for selecting the right method for your projects. Whether you choose MIG, TIG, stick, or flux-cored welding, each has its advantages and applications in various industries. By exploring and experimenting with different welding techniques, you can expand your skills and capabilities as a welder. The versatility and significance of welding in modern industries highlight its importance as a foundational process in manufacturing and construction.