Produce durable, high-quality parts cost-effectively, with lower tooling expenses compared to injection molding.

STEP Ι STP Ι SLDPRT Ι IPT Ι PRT Ι SAT files

Compression Molding

Compression molding has several unique advantages compared to other molding processes. For instance, it can produce large and intricate parts with minimal waste and cost-effectiveness. PROTO MFG’s compression molding process allows for greater design flexibility and enables the creation of accurate and strong parts. Additionally, compression molding is suitable for manufacturing fiber-reinforced polymer composites, which offer high strength and durability compared to conventional materials.

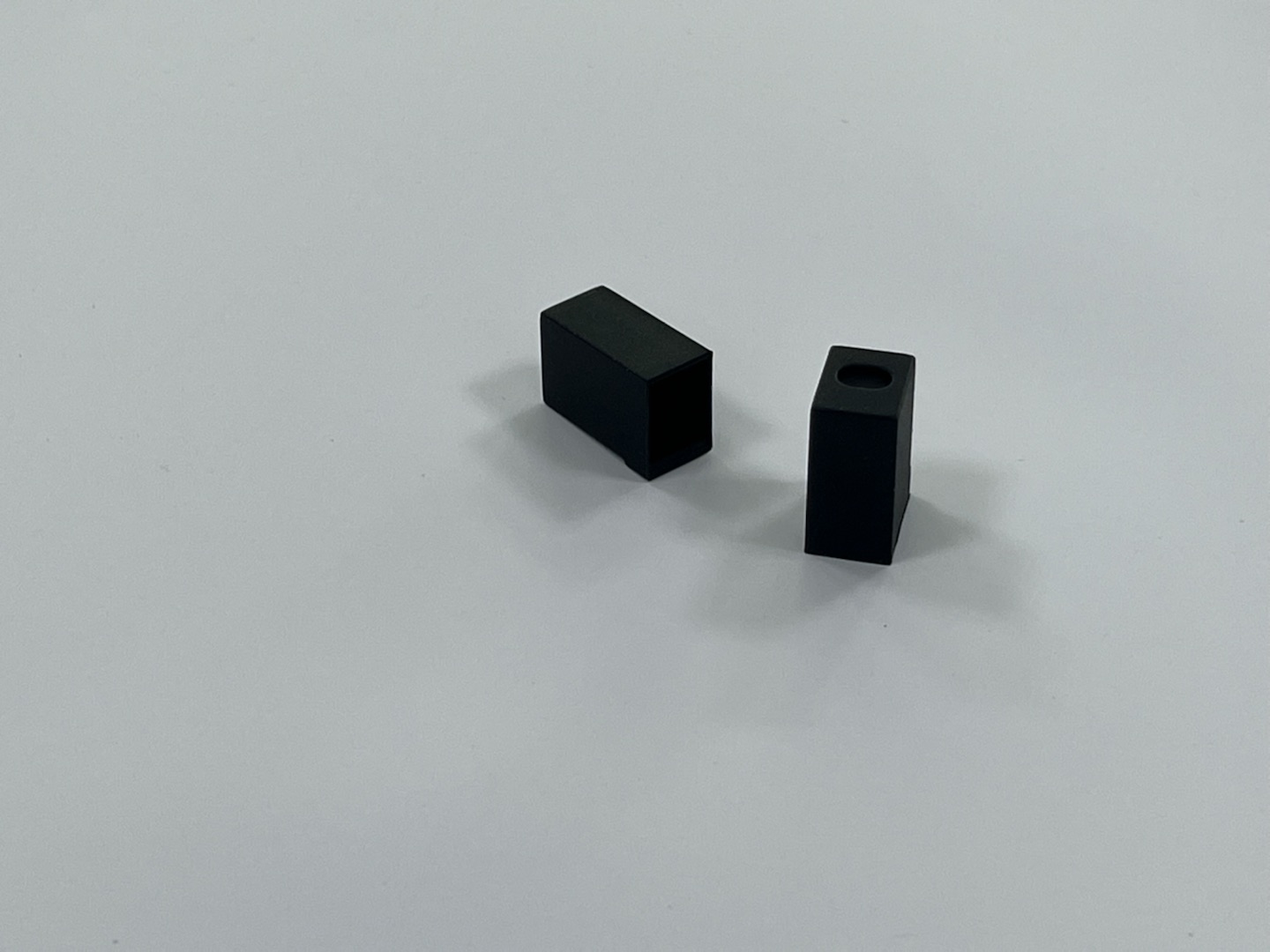

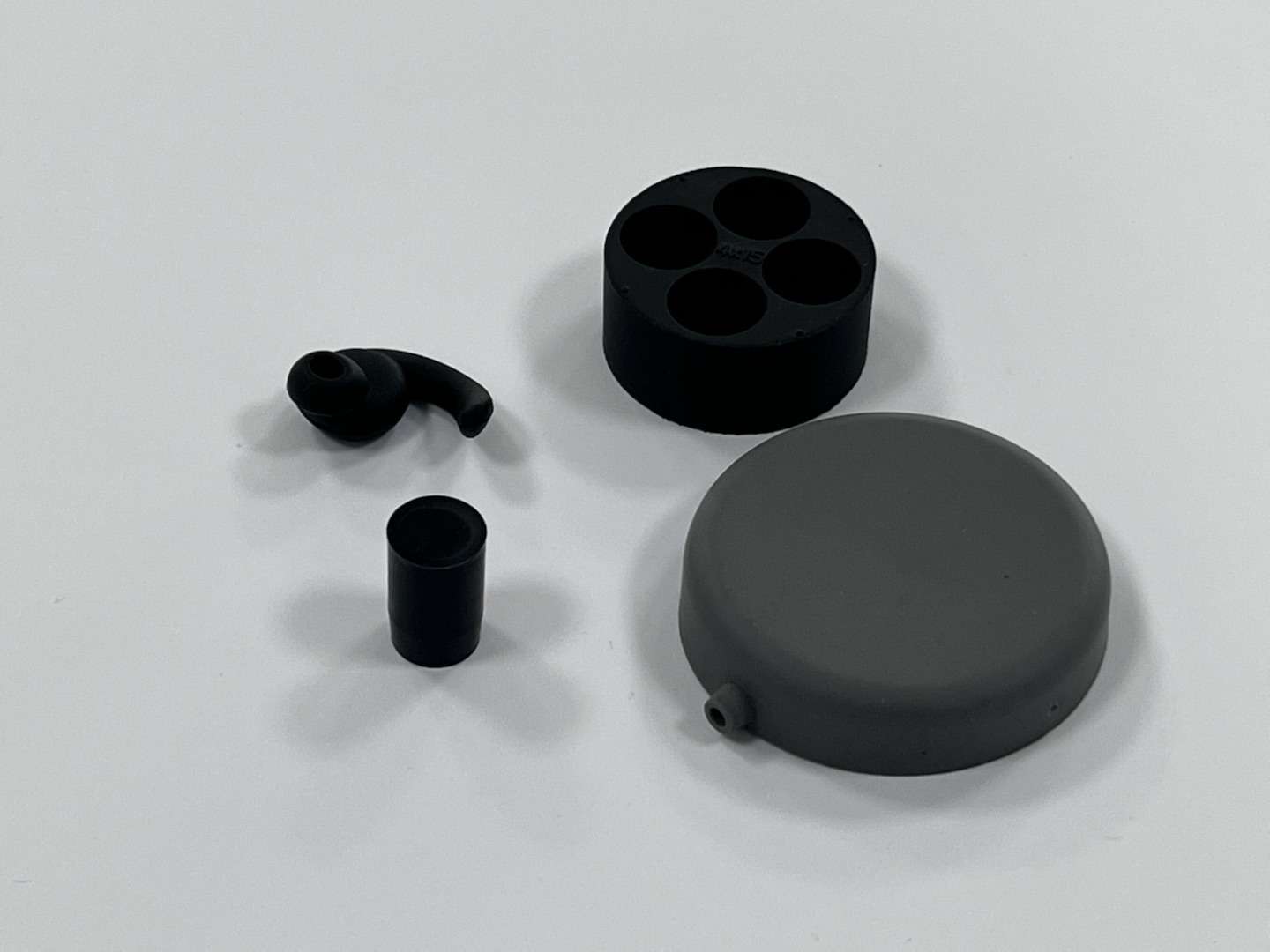

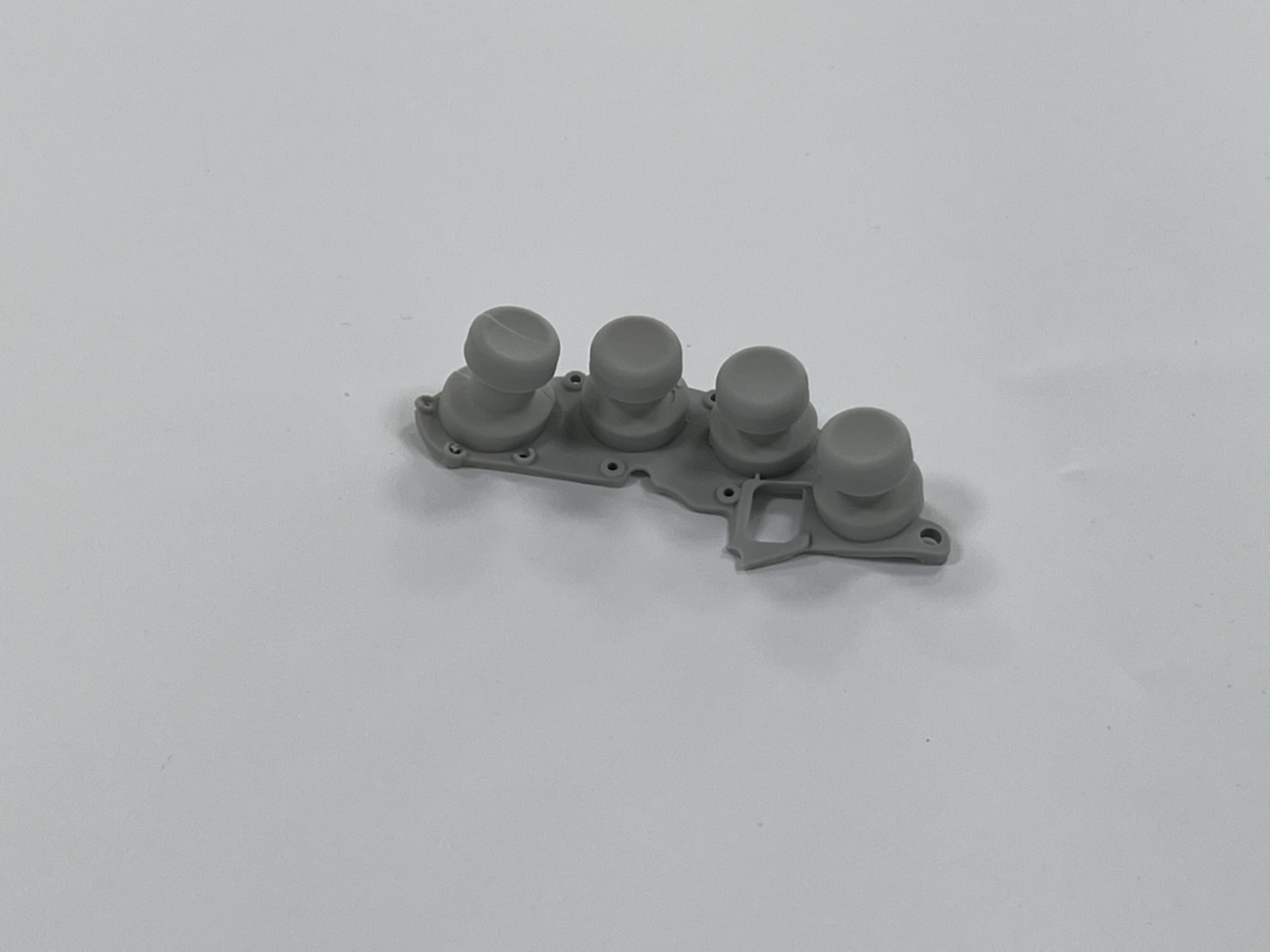

Compression Molding Parts

Compression molding is a process of converting raw materials into finished parts using heat and pressure. In this process, the material is placed into a cavity between two matched molds and heated until it melts. Once the material is melted, the mold is closed, and pressure is applied to ensure that the material takes the shape of the mold. The injection of air into the mold ensures that the final product is uniform in density.

PROTO MFG is a leading provider of compression molding services, with decades of experience in this field. Our team of experts can assist clients in every step of the process, from material selection to final product testing. We use advanced equipment and technologies to ensure high precision and accuracy, and our quality control standards are of the highest level. Furthermore, we offer excellent customer service, fast turnaround times, and competitive pricing.

PROTO MFG’s compression molding process involves several steps, including material preparation, mold preparation, loading, compression, and cooling. Material preparation involves mixing the raw materials and additives to achieve the desired properties. Mold preparation involves cleaning and heating the mold to the required temperature. Loading and compression involve putting the mixed material into the mold cavity and then compressing it under high pressure. Finally, the part is cooled down, and the mold is removed to reveal the finished product.

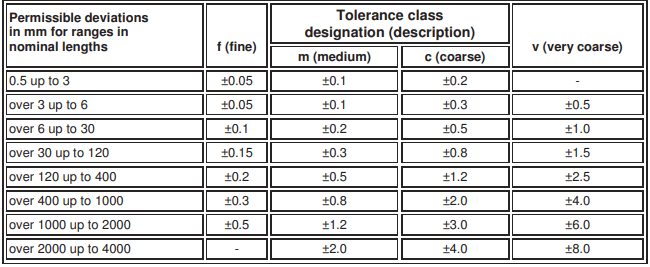

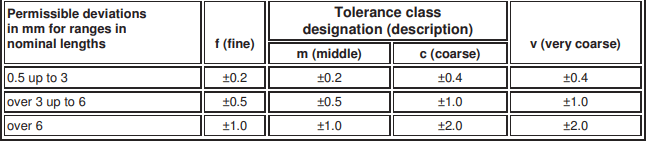

General Tolerance / According to the Drawings requirements

The Best Compression Molding Service In China

We provide high-quality mechanical parts production solutions to support your product development and go to the market needs with Compression molding technologies. Proto MFG’s manufacturing solutions will give you Stable, committed, on-time, quality, and smooth communication to create, test and refine in ways you never thought possible so you can go to market faster.

1. Fast Turnaround & Affordable

2. DFM feedback to optimize your designs

3. Quick pricing within 4-24 hours

4. On-demand production updates regularly

5. Material certifications & certificates of conformity

6. Free dimensional inspection reports

7. Tight tolerances

8. Sign and follow the NDA

Revolutionizing Production with Compression Molding At PROTO MFG

From aerospace to food processing, various industries require quality products and components to operate. The production of these parts demands a specific mold or tool that will help achieve the required shape and size. Compression molding, manufacturing specialists, have been providing high-quality molds to numerous sectors since silicone was discovered. This article will focus on how compression molding help provide parts production and their application in various industries.

1. Automotive Industry

The automotive industry requires the production of numerous parts, including gaskets, seals, and tubes. Compression Molds aid in the production of these parts by offering resistance to chemical reactions commonly found in automotive operations. Additionally, silicone elastic properties aid in the production of parts with complex shapes and sizes, making it a vital tool in the industry.

2. Medical Industry

Compression molding are essential in the production of medical parts such as catheters, syringe gaskets, and valve seals. These medical parts require precision manufacturing, and silicone molds provide that. In medical manufacturing, having a mold that can produce parts close to the real thing is critical. A compression mold can replicate the size and texture to the finest detail, making it a valuable tool in the medical field.

3. Food Industry

The food industry requires molds for making baked goods, chocolate, and other foodstuffs. Compression molding provide the non-stick feature, which is essential when working with food. Additionally, the precise cuts on silicone molds help achieve the desired shape and design, giving the food product an added appeal. The ability to bake and freeze the molds also allows for flexibility when producing multiple products.

4. Aerospace Industry

In the aerospace industry, precision, quality, and durability are essential attributes for all parts produced. Silicone molds provide an excellent solution for the production of parts. The stiffness of the silicone material helps in the production of complicated parts and helps reproduce parts to proximity. The high level of purity in silicone also provides the necessary performance characteristics and quality demanded.

5. Industrial Machinery Industry

Industrial machinery production requires molds for creating seals, gaskets, bushings, and custom parts. Compression molding provide an ideal solution for manufacturing in the machinery sector. The silicone’s durable quality and the ability to withstand high temperatures and pressure make it suitable for making high-performance parts.

Compression molds have become one of the most essential tools in multiple industries. Their properties such as flexibility, easy to design, and ability to mold precise shapes, make them invaluable assets for any business looking to produce parts at high quality and standard. The adoption of compression molding has transformed production processes, increased efficiency, and improved quality control. Its application in industries such as the automotive, medical, aerospace, industrial machinery, and food industries have led to the emergence of innovative products and services. A fact that showcases silicone molds, make it possible for individuals and businesses to realize their manufacturing goals.