The traditional machining methods we often hear are turning, pliers, washing, planing, and grinding. With the development of mechanical technology, in terms of mechanical processing, electroplating, wire cutting, casting, forging, powder processing, etc. have also appeared.

Turning is mainly due to the rotation of the workpiece, and the turning tool is used to cut the workpiece into the required shape. When the tool moves along the parallel axis of rotation, the inner and outer cylindrical surfaces can be obtained. The formation of the cone surface is the movement of the tool along the oblique line that intersects with the axis. The surface of rotation is formed on a profiling lathe or CNC lathe, where the tool is controlled to feed along a curve. Another type of production of rotating curved surfaces uses forming turning tools and transverse feed. In addition, turning can also be used to process threaded surfaces, end planes and eccentric shafts.

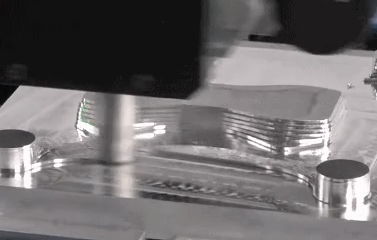

Milling mainly relies on the rotation of the tool. Milling is divided into horizontal milling and vertical milling. The plane of horizontal milling is formed by the edge on the outer surface of the milling cutter. End milling is formed by the end edge of the milling cutter. To achieve higher cutting speeds and increase productivity, the milling cutter speed can be increased. However, due to the impact caused by the cutting in and out of the milling cutter teeth, the cutting process is prone to vibration, thus limiting the improvement of surface quality.

Planing is mainly a reciprocating linear motion of the tool to cut the workpiece. Therefore, the speed of planing is relatively low and thus the productivity is low. However, the accuracy and surface roughness of planing are smoother than those of milling.

Grinding mainly relies on the grinding wheel and abrasive tools to process the workpiece, and it relies on the rotation of the grinding wheel. When the grinding wheel is grinding, the abrasive grains on the grinding wheel mainly perform three functions: cutting, engraving and sliding on the surface of the workpiece. The abrasive particles themselves also gradually grind from sharp to blunt, making the cutting effect worse and the cutting force larger. Therefore, after grinding for a certain period of time, the grinding wheel needs to be dressed with a diamond turning tool.

Tooth surface processing is a new processing method. This processing method is divided into two categories: one is the forming method, and the other is the generation method. The forming method mainly uses ordinary milling machines for processing. The tool is a forming milling cutter, which requires two simple forming movements: rotational movement and linear movement of the tool. Commonly used machine tools for processing tooth surfaces by the generation method are gear hobbing machines, gear shaping machines, etc. When choosing a machining method, you must consider many aspects and choose an appropriate method, so that the accuracy and quality of the products produced can be guaranteed. With the continuous development of science and technology, the forms of mechanical processing are also constantly increasing. In addition to the several common methods introduced in this article, there are many processing methods. Everyone is welcome to leave additional messages.