CNC milling is one of the most popular CNC machining services and technologies and is used in almost every industry from automotive to aerospace. This is due to the high levels of precision, repeatability, and production rate made possible with CNC mills. This article will describe CNC mills, including their various parts, how they work, and the different types of CNC mills available.

What is CNC Milling?

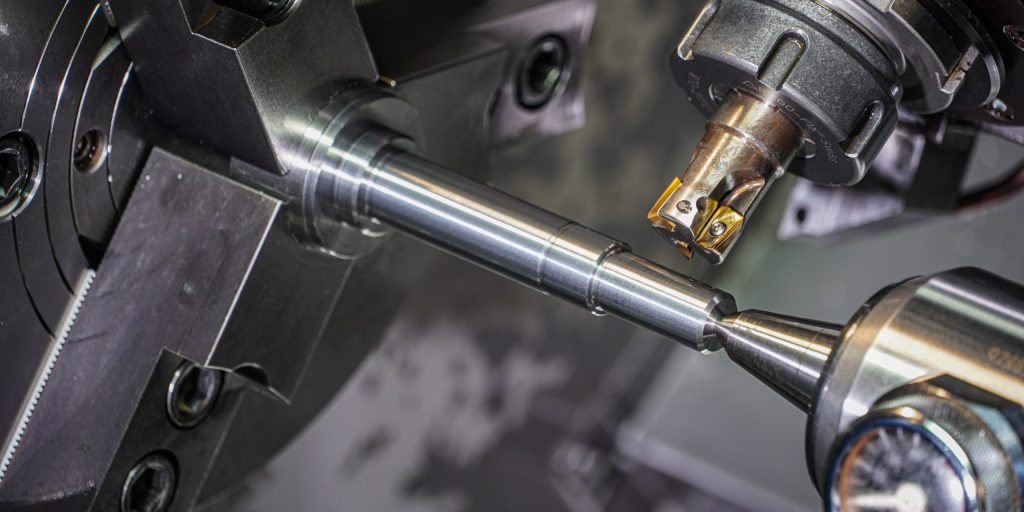

CNC milling is an automated, subtractive manufacturing technology designed to remove material in a controlled, pre-programmed manner to produce parts. Almost any material can be processed using CNC milling, including metal, plastic, and wood. CNC mills require specialized operators, but once programmed, they can produces parts without continuous supervision. Engine blocks, gears, brackets, and various other components are produced with CNC mills.

A quick note on CNC milling vs CNC turning: CNC milling works by a moving tool across a stationary workpiece, whereas CNC turning rotates the workpiece, and a stationary tool does the cutting.

The CNC Milling Process

A CNC mill introduces a cutting tool into a stationary workpiece, automatically driving the tool through the material as the tool spins. Below is the basic workflow for CNC machine milling:

Design: The part is designed with 3D CAD (Computer-Aided Design) software using relevant DFM (Design for Manufacturing) principles. You can check out our free CNC Design Guide for some expert tips on designing your next CNC milled part.

CAM: Once the CAD design is complete, it must be processed using CAM (Computer-Aided Manufacturing) software. CAM helps convert the 3D model into a set of instructions to tell the machine how to make it — i.e. which cutting tool to use when, the speeds and feeds, when to engage coolant, and when to probe specific features. Some may know these instructions as G-code for CNC machining, or have programmed CNC machine tooling and table positioning based off a coordinate system. Thankfully, this programming is mostly automated with CAM software.

Machining: The output from the CAM software is then loaded into the CNC machine, the workpieces (raw materials) are loaded into fixtures, and the CNC milling takes place. After the parts are finished, they’re unloaded from the CNC milling machine for assembly, consumer delivery, or post-processing.

Parts of a CNC Mill

Listed below are the critial components that make up a standard CNC mill:

Spindle: The spindle of a CNC mill is designed to spin at a very high rotational speed while withstanding high lateral loads without excessive deflection. The spindle is driven with a variable-speed motor and the rotation is transmitted to the cutting tool via a tool holder.

Tool Holder: The tool holder is clamped to the spindle using hydraulics and is designed to clamp onto the tool.

Machine Bed: The machine bed is the base structure on which the machine’s other components are mounted. It’s typically made of cast iron or heavy steel to provide a stable foundation for the machine. The bed includes the X, Y, and Z-axis ways — the linear guides or ball screws that control the movement of the machine’s components along the axes. The bed also houses the machine’s electrical and mechanical systems, including the control panel, spindle, and drive motors. The machine bed is the foundation of the machine and its rigidity is vital for accuracy and precision.

Worktable: The worktable of a CNC mill sits on the machine bed. It is typically flat, with slots or holes for the clamps used to hold the workpiece. Standard CNC mills have a worktable that moves in the X and Y directions, whereas some advanced 5-axis CNC mills can swing and rotate the bed to facilitate more advanced machining operations.

Drive Components: Servo motors are used to move the machine bed and spindle. These servo motors use linear drive elements, like ball screws, to transform rotational motion into precise linear motion. Linear guides are used to ensure accurate and precise motion along the relevant axis with few deviations.

Coolant Tank: The coolant tank of a CNC mill is used to store coolant used during machining. The coolant is pumped to the machine tool via a coolant line — but in more advanced machines, coolant is supplied directly to the tool through the spindle.

Controller: The controller refers to the electrical hardware used to communicate the machining instructions to the various electro-mechanical components of the machine, including drive motors, coolant pumps, and chip conveyors.

Interface: The interface of a CNC mill is often a screen and keyboard attached to the machine. The machine can be directly controlled using this interface, and some very basic CNC programming can also be carried out through the same interface.

Benefits of CNC Milling

CNC milling has various advantages over traditional milling and even other types of CNC machining, some of which are listed below:

Improved productivity

Reduced labor cost

Increased safety

Higher consistency

Better finish quality

Increased flexibility

Different Types of CNC Milling Machines

CNC machines come in a wide range of configurations. In general, there are two main styles of CNC mill, namely VMC (Vertical Machining Center) and HMC (Horizontal Machining Center). A VMC typically has the spindle vertically along its Z-axis whereas an HMC has the spindle horizontally along its Z-axis as shown in Figure 2 below:

Machine Axes

CNC mills can further be categorized by the number of translation and rotational axes in which they can be moved — these are often referred to as degrees of freedom. There can be a maximum of 6 degrees of freedom, namely 3 transitional (X, Y, Z) and 3 rotational (A, B, C) degrees of freedom. A higher degree of freedom results in a machine that is more capable of producing complex components because it can position the milling tool in more locations and at multiple angles. The most common multi-axis CNC machines have 3, 4, or 5 axes. 5-Axis CNC milling machines are the most advanced machines, with the most popular configurations being the trunnion and gantry styles.

CNC Mill Add-Ons

In addition to the basic components of a CNC mill, there exists a range of add-on equipment that can dramatically increase CNC milling efficiency. These are listed below:

Automatic Tool Changers: Automatic tool changers are designed to automatically swap out different tools during machining by selecting a tool from a tool library. This helps increase machining efficiency by eliminating the need for an operator to stop the machine to manually change out a tool.

Robotic Arms: Robotic arms can be integrated with CNC mills to perform a range of tasks like automatically loading raw material into the machine and removing or repositioning parts after machining is complete. In addition to this, robot arms can be used to change out workholding devices and fixtures. This further automates a CNC mill to allow for lights-out manufacturing and lower operating costs.

Chip Conveyors: A chip conveyor removes chips from the mill during machining. This helps keep the machine clean, and production does not need to be stopped to clean chips from the machine, which results in higher machining uptime.

Types of CNC Milling Operations

CNC mills remove material by moving a spinning tool through the raw material, physically displacing the material. However, there are multiple cutting strategies and tools that can be employed to produce a part; some of the most popular are listed below:

Plain Milling: This is the most basic operation possible on a CNC mill, that’s used to produce flat faces parallel to the bed of the CNC mill.

Face Milling: Face milling is similar to plain milling, however, a much larger diameter tool is used and the depth of cut is only a fraction of plain milling. Face milling produces a large, flat surface.

Contour Milling: Contour milling refers to the process of producing curved or contoured surfaces. In most cases, the rough shape is first machined, then a final contour pass is performed using a tool like a ball end mill to get the desired shape.

Angular Milling: Angular milling refers to the process of milling a flat surface that is not parallel to the bed or the spindle axis. An example would be a chamfer on the corner of the part.

Side Milling: This refers to the process of milling a flat, vertical surface on the side of the part.

Groove or Slot Milling: Slotting refers to the process of cutting a groove inside the raw material. This slot can either pass through the material or, alternatively, only extend a fraction of the way through the material.

Hole Drilling: Holes are typically machined using a drill. However, larger holes can be machined with an end mill that cuts the hole by spiraling down into the workpiece.

Reaming: After drilling, the hole can be reamed to achieve a precise diameter. Reamed holes are often used to accurately position items with locating pins.

Hole Tapping: Hole tapping is performed on a pre-drilled hole. The tap is introduced into the hole and either cuts or forms the thread at the required pitch to be able to accept a fastening element like a bolt.

Gang Milling: Gang milling is when multiple milling cutters engage the workpiece at the same time.

Limitations of CNC Milling

Despite the widespread adoption of CNC mills, there are still some disadvantages:

Expensive Equipment: CNC mills are high-precision automated tools, which means they are significantly more expensive than manual machines. The cost of a CNC mill can only be justified if there is sufficient production volume.

Advanced Operation: CNC mills require skilled programmers and operators, and training these operators can be expensive and time-consuming.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.