In modern times, metal casting encompasses sand casting, investment casting, lost foam casting, permanent mold casting, centrifugal casting, and die casting. Metal casting refers to the entire industry of injecting liquid metal into molds to obtain desired shapes.

Sand casting, investment casting, and lost foam casting use gravity to fill molds. Once the liquid solidifies, the formed metal part is extracted by destroying the mold, which is disposable. Mold-making is integral to the production process, guiding the metal’s flow to fill the mold cavity, impacting production time. Due to slow heat dissipation of mold materials, cooling time is prolonged, extending casting production cycles.

Metal mold casting, also known as permanent mold casting, is akin to die casting. It involves pouring liquid metal into metallic molds to obtain castings. These molds, made of metal, are reusable for hundreds to thousands of times. There are limitations in weight and shape for castings produced by metal mold casting. Similar to sand casting, this process utilizes gravity to fill molds. The metal flow is slow due to gravity, but efficiency is improved as molds are made of steel, which has good thermal conductivity.

Centrifugal casting involves pouring liquid metal into rotating molds, shaping and solidifying the casting through centrifugal force. The machine used for centrifugal casting is called a centrifugal casting machine. Depending on the casting’s shape, size, and production batch, molds for centrifugal casting can be non-metallic (such as sand, shell, or investment shell), metallic, or lined with coatings or resin sand layers.

Die casting is a process where metal solution is injected into molds under high pressure, cooling to shape. It’s the most efficient method for mass-producing metal products in the metalworking industry, covering various sectors like automotive, electrical equipment, weaponry, power tools, computers, toys, etc. Die castings were commercially used as early as 1892 for parts in phonographs and cash registers. Later, the HHFranklin Company extensively used die casting for Babbitt alloy bearings in automotive connecting rods. Today, aluminum alloy castings are most widely used, followed by zinc alloys. Advancements in modern science, metallurgical control, and research enable further refinement of metals, producing new alloys with higher strength and stability.

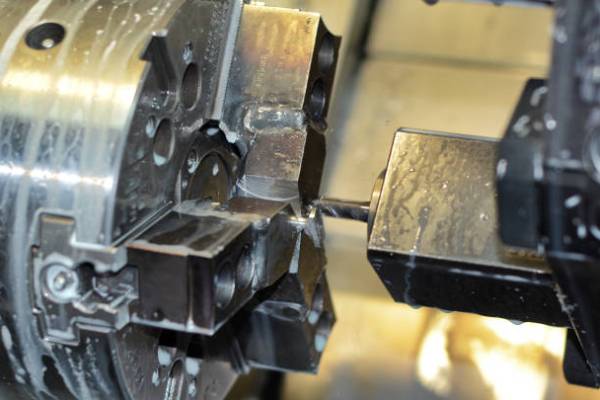

The main advantage of die casting is producing net or near-net shapes. They are cast to final dimensions, minimizing or eliminating machining operations, greatly enhancing production efficiency and lowering production costs. Therefore, die casting stands as the most popular process in modern hardware parts manufacturing.