Blog

What is Laser Cutting?

Jan,09 2024

At one time, lasers were nothing more than science fiction dreams. In the last 60 years, we’ve transitioned from imaginary cosmic ray guns to harnessing the power of light strategically. Today, las……

How to Improve Surface Finish on Machined Parts

Jan,09 2024

Machining of metal or plastic plays a huge role in parts production. In many cases, machined surface finishes are more than adequate for end-use applications, but because part surfaces are cut, rat……

Fillets vs. Chamfers: How to Handle Edges and Corners in CNC Machining Design

Jan,09 2024

The crisp, sharp edges in 3D models don’t always translate well to the real world and real-world objects. Rounded corners and edges are easier on the eyes, according to experts. They also make part……

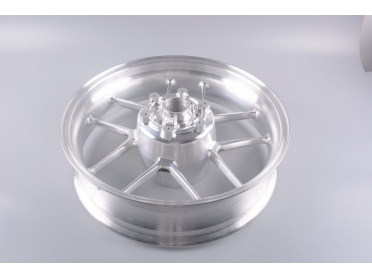

Why is Aluminum So Popular?

Jan,09 2024

Aluminum is a common and popular metal that’s found everywhere and used in a stunningly wide range of parts and products: automotive parts, aerospace components, boat and marine gear, consumer elec……

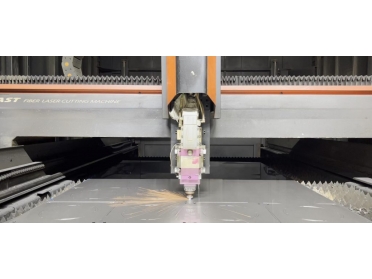

3 Ways to Accelerate Sheet Metal Part Production

Jan,09 2024

Sheet metal parts are widely used by various industries due to their versatility, strength, and relative cost-effectiveness to produce. As production batch sizes become smaller and SKU counts grow,……

The Advantages and Disadvantages of Injection Molding

Jan,09 2024

Injection molding has a number of advantages. It minimises molding costs and is a highly repeatable way of producing plastic or elastomeric parts with high precision. Once set up, it can manufactur……

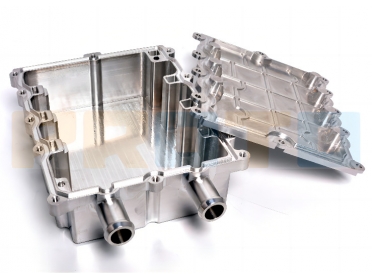

7 Top Benefits of CNC Machining

Jan,08 2024

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offer……

Comparing Type II and Type III Anodizing for Machined Parts

Jan,08 2024

All metal machined parts are susceptible to corrosion. It’s just the nature of chemistry. But if you choose your materials thoughtfully and use specialized treatments, you can reduce negative effec……

15 Types of Milling Operations

Jan,08 2024

Milling has several meanings, most of which relate to circular tool cutting of materials. In particular, the most important definition of milling is the use of generally multi-tooth, rotating cutti……

Compression Molding Versus Injection Molding

Jan,08 2024

Compression molding vs. injection molding is a contest between two of the most popular ways to mold plastic and rubber parts. Each process has advantages and applications, but what’s the best choic……

What is a Machining Center: Definition, Types, Components & Applications

Jan,08 2024

In the world of manufacturing, a machining center (MC) serves as the cornerstone for modern industrial applications. But what exactly is a machining center, and how does it contribute to the field ……

Anodized Aluminum Colors: What You Need to Know

Jan,08 2024

Aluminum that has undergone the electrochemical process of anodization is referred to as anodized aluminum. This procedure improves its longevity and resistance, but it also enables you to apply co……