Blog

What are the common problems with prototype silicone replica molds?

Jan,24 2024

Vacuum copy molding and low-pressure infusion are common methods for prototyping. The principles of the two appear to be similar on the surface. An original version can be made through CNC processi……

What’s the Difference? Alloy Steel vs Carbon Steel

Jan,24 2024

In contrast to alloy steel, which also contains other elements to change the metal’s properties, carbon steel is simply iron with carbon added to it.Not that carbon steel is only made of carbon and……

CNC machining | Aluminum alloy materials you must be familiar with (2)

Jan,24 2024

Heat treatment is a common conditioning process in which aluminum alloys are heat treated, which changes the material properties of many metals at a chemical level, such as increasing hardness and ……

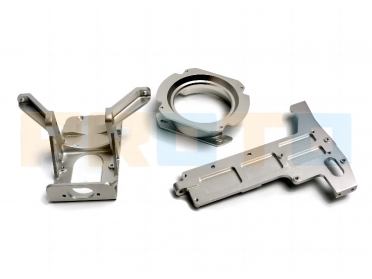

CNC machining | What are the process options for manufacturing aluminum alloy prototypes?

Jan,24 2024

Among many metal materials, aluminum has become the metal material of choice for many engineers because of its excellent appearance, excellent performance and affordable price. It can be said that ……

CNC machining | What are the advantages and disadvantages of aluminum plates?

Jan,24 2024

As a common metal material, aluminum plate is widely used in industry and life. It has many advantages and also some disadvantages.First of all, one of the advantages of aluminum panels is their li……

Prototype model丨What is the process and function of wire drawing for aluminum alloy prototype model?

Jan,24 2024

Brushing is a repair process that can provide an aesthetic effect. If there are local scratches on the metal surface, use a wire drawing machine to make consistent scratches on the entire surface a……

CNC plastic processing tips

Jan,24 2024

CNC machining has traditionally been considered a machining method. However, modern industry has ever-increasing precision requirements for parts in all possible materials. This is why CNC plastic ……

5 common sheet metal forming processes

Jan,23 2024

Sheet metal (usually steel or aluminum) plays an important role in construction and manufacturing. In the construction industry, it is used as buildings and shells or roofs; in manufacturing, sheet……

Why is CNC milling suitable for medical device manufacturing?

Jan,23 2024

In medical manufacturing, every micron counts. The accuracy, reliability and consistency required in this industry are of very high standards. So, when the question arises – why choose CNC milling ……

Application of CNC milling in automobile production

Jan,23 2024

Milling provides automotive manufacturing with unrivaled precision and flexibility. A variety of vehicle systems utilize CNC milling to produce parts, and each manufacturing method has its own uniq……

Benefits And Techniques Of Small Batch CNC Machining

Jan,23 2024

In the realm of manufacturing, the landscape has evolved to favor flexibility and efficiency. Small batch CNC machining involves small-scale production of products or components, typically between ……

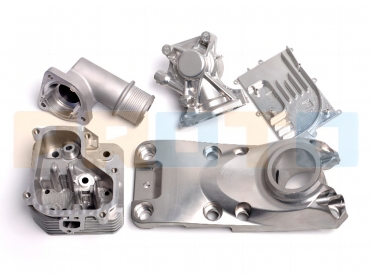

Processing skills that should be paid attention to when processing aluminum alloy shells

Jan,23 2024

Aluminum alloy accessories and products are favored by many industries because of their light weight and exquisite appearance, and are increasingly used in industry and daily necessities. Especiall……