admin

7 Top Benefits of CNC Machining

Jan,08 2024

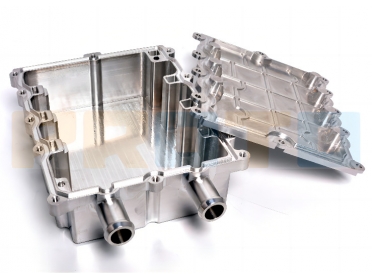

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offer……

Comparing Type II and Type III Anodizing for Machined Parts

Jan,08 2024

All metal machined parts are susceptible to corrosion. It’s just the nature of chemistry. But if you choose your materials thoughtfully and use specialized treatments, you can reduce negative effec……

15 Types of Milling Operations

Jan,08 2024

Milling has several meanings, most of which relate to circular tool cutting of materials. In particular, the most important definition of milling is the use of generally multi-tooth, rotating cutti……

Compression Molding Versus Injection Molding

Jan,08 2024

Compression molding vs. injection molding is a contest between two of the most popular ways to mold plastic and rubber parts. Each process has advantages and applications, but what’s the best choic……

What is a Machining Center: Definition, Types, Components & Applications

Jan,08 2024

In the world of manufacturing, a machining center (MC) serves as the cornerstone for modern industrial applications. But what exactly is a machining center, and how does it contribute to the field ……

Anodized Aluminum Colors: What You Need to Know

Jan,08 2024

Aluminum that has undergone the electrochemical process of anodization is referred to as anodized aluminum. This procedure improves its longevity and resistance, but it also enables you to apply co……

What is Low-Volume Production?

Jan,08 2024

Introducing a new product to the market is always a risky endeavor. Many different factors can derail a new product’s launch. One of the best ways of mitigating these risks is to adopt low-volume p……

9 Different Types of Bronze

Jan,08 2024

Bronze alloys come in a variety of compositions, each designed for a particular use. With its great mechanical prowess and 9–14% aluminum enrichment, aluminum bronze is a reliable option for naval ……

Electrical Discharge Machining: How It Works, Types and Real-World Applications

Jan,08 2024

Electrical Discharge Machining (EDM) is a nonconventional machining process used primarily for tasks that would be unachievable with conventional methods. It uses electricity to erode the surface o……

How To Mass Produce a Product: History, Process, Advantages, and Disadvantages

Jan,08 2024

Mass production is the manufacturing of a large number of similar products using an efficient means. It often incorporates the use of automated processes and machinery and is highly repetitive. Thi……

6 Different Ways of Coatings

Jan,08 2024

The coatings on industrial items are often integral to their material protection measures. Some of the most common industrial forms are: resilient epoxy coatings, versatile polyurethane coatings, a……

Concept to Products - Simplified Steps

Jul,11 2023

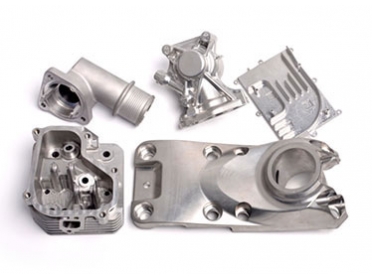

The prototype stage is where you bring the product to life. This stage involves the creation of a preliminary version of the product. You can use PROTO MFG's manufacturing services(CNC machining, sheet metal, urethane casting, compression molding, 3D printing) to create an initial model or have a single unit created. The created prototype is a preliminary test of the product, and there will be several modifications to ensure it aligns with the specifications.