Modern industry requires parts to be machined quickly. The demand for rapid prototypes or custom parts is increasing month by month. Customers want their orders to be completed faster and require parts to be more accurate than before. Aluminium, one of the most commonly used alloys in modern manufacturing, seems to be the best material. It is light, strong, durable and corrosion resistant. One of the modern and successful CNC aluminium milling methods is called high-speed machining. The main difference with conventional milling is that the speed of HSM is much higher and the operator can increase the feed rate. Therefore, HSM milling of aluminium is very beneficial in many unexpected ways. Here are the advantages of choosing HSM aluminium milling over conventional milling.

By increasing the cutting speed to 3 times the conventional aluminium milling speed, the feed rate can be increased to 2 times (when machining softer aluminium alloys). As we know, the machining feed rate is the parameter that determines the productivity of the entire milling process. Nevertheless, the efficiency of high-speed machining can be significantly higher than that of conventional milling. The machinability of aluminium allows the spindle speed to be increased to 18,000 rpm or more, resulting in amazing material removal rates.

Such material removal rates make aluminium machining with HSM strategies very profitable in the automotive and aerospace industries. In the first case, automotive prototypes require a lot of material removal in as few milling setups as possible. In the second case, there are many long and large parts with deep slots (they must be lightweight, so most are machined as a set of intersecting ribs) and thin walls. L, the proportion of aluminium alloys in aircraft and rockets can be as high as 80%.

Practice has shown that the cutting temperature changes as the speed increases. Initially, the higher the speed, the higher the temperature. However, as the speed increases, the temperature starts to drop sharply until, at a certain point, it no longer matters. Increasing the cutting speed can only reduce the temperature to a small extent. This transition is the hallmark of high-speed machining. For example, when milling aluminium at 300-500 m/min, the temperature can reach 600-800 degrees. However, if we increase the speed to 1200 m/min, the temperature drops to less than 200 degrees, and at 1800 m/min the temperature is only 150 degrees. From this point of view, higher cutting speeds are meaningless.

Think about it, only 150-200 degrees! The properties of the material in the cutting area are not changed by local hot working, the metal grain does not increase and the cooling requirement is much lower. I think this is a big advantage.

This may seem strange, as higher cutting speeds result in greater tool wear, but if we compare the amount of material removed by a tool in high-speed milling of aluminium with conventional milling, rather than in terms of tool life in minutes, we see that the difference is clear and in favour of high-speed milling of aluminium. What is the reason for the increased tool life? Firstly, the cutting temperature is lower, which means the tool material is stronger. Secondly, the chip width is smaller in high-speed milling (the tool rotates faster, cutting thinner chips even at higher feed rates).

Also, when machining aluminum, a major problem is that aluminum is too soft and will stick to the cutting edge of the tool during machining. This reduces the sharpness of the tool and increases cutting forces, which reduces tool life. But this does not happen at high speeds. The aluminum just stays away.

We all think that the higher the feed, the lower the surface finish on aluminum, because the tool cutting edge moves farther than it can in one turn and cut it off. Generally, this results in wider chips, higher cutting forces and a poorer surface finish. However, in high-speed machining, despite the higher feed, the tool speed is higher, so the chips are actually thinner than in conventional milling. In addition, because the cutting forces are lower, vibrations are also lower.

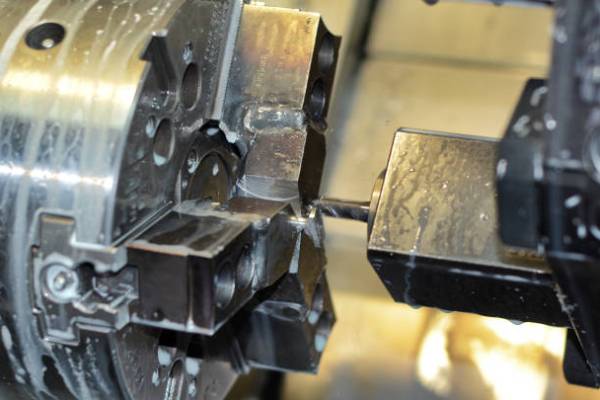

One of the main issues when milling a part cavity with an end mill is related to the angle of the milling cavity. The end mill must be rotated 90 degrees to machine the groove, and the material to be removed (from both sides of the groove) has doubled. This leads to a local increase in cutting forces, which is very detrimental to tool life and part accuracy. However, HSM Aluminum Milling has many predetermined tool path generation strategies, including a constant tool engagement angle. This means that the tool gradually approaches this angle while machining all the material around it in a circular trajectory. In this way, the cutting forces remain constant and the accuracy remains the same. In addition, the tool life is extended.

Are you looking for a reputable partner for your parts fabrication and machining projects? Look no further. At PROTO MFG, we specialize in CNC machining and related technologies, including sheet metal fabrication, rapid prototyping, etc. Whether it is a project with a simple design or parts with complex geometries, do not hesitate to contact us today!