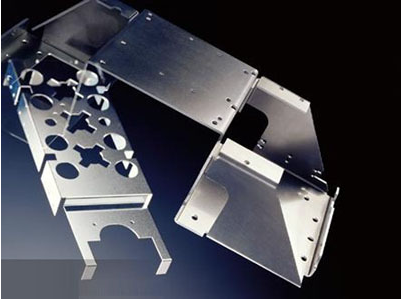

Sheet metal processing is the processing of metal plates of parts, which is an important processing technology in China’s industry. As long as it is a product with hardware content, it is inseparable from sheet metal processing. Because of this, sheet metal processing has an important impact on people’s production and life.

The sheet metal processing industry has developed like never before and has developed specific technological processes. Specifically, processing mainly includes four steps: one is to select processing materials, the second is to review the drawing, the third is to expand the drawing, and the fourth is to cut the material, fitter and other processing.

In the previous sheet metal fabrication process, the fabricator played an important role. For example, in the drawing review, the processing personnel must ensure that they understand every content in the drawing before they can carry out subsequent processing. For the ever-changing development of the times, this old routine is obviously difficult for my processing technology to meet the current needs, and we must innovate and upgrade to realize the mechanization and automation of processing.

The application of mechanized automation technology to the sheet metal processing industry can not only improve processing efficiency, reduce errors, and achieve real assembly line production, but also greatly reduce the pressure on processing personnel and improve the overall quality of sheet metal processing. It can be said that the realization of mechanized automation of sheet metal processing is the requirement of China’s industrial development, and it is also one of the important symbols of industrial development, which indicates the advent of the era of industrial mechanization and automation.

Moreover, sheet metal processing has a wide range of applications and is closely related to many industries. Mechanization and automation can significantly improve the productivity of other enterprises, reduce costs, and promote the development of the industry.

Automation helps businesses meet huge demands. They have the ability to produce a large number of products that meet high-quality specifications and meet requirements with shortened lead times. Simply put, automation can increase productivity because it means that equipment can run for longer periods of time with little input from labor.

At the same time, the automated system allows the management of the sheet metal fabrication company to monitor all processes at all times. This potentially tedious manual labor is left to the machine, which can be managed anywhere (the senior team doesn’t even have to be on the shop floor). All of this effectively enables businesses to provide round-the-clock service to their customers, allowing them to take a leading position in a saturated market.