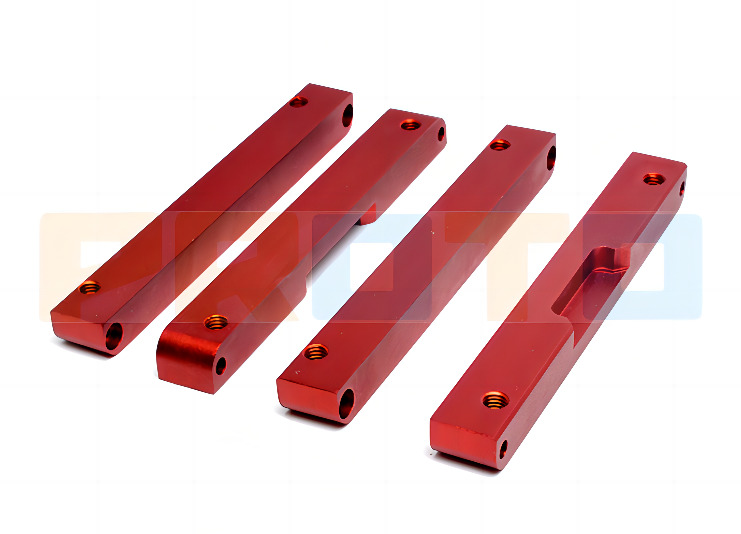

Most aluminum alloy prototypes are processed by CNC and are one of the most common metal prototypes. The surface treatment is usually oxidation. So why does the aluminum alloy prototype need to be oxidized? Let’s take a look at how aluminum alloy prototypes oxidize and what are the functions of aluminum alloy prototype oxidation.

Aluminum alloy prototype oxidation treatment process

Aluminum alloy prototype oxidation is a process commonly used by prototype factories for surface treatment of aluminum alloy prototypes. Sandblasting is usually required before oxidation, otherwise it will affect the aesthetics of the aluminum alloy prototype.

If the aluminum alloy prototype you want to make is of natural color, you only need to sand it smooth and then sandblast it.

Let’s talk about the issues that need to be paid attention to when sandblasting aluminum alloy prototypes before oxidation treatment:

Conditions for coloring the oxide film of aluminum alloy prototypes

What electrolyte should be selected for anodizing?

1.The more widely used is sulfuric acid DC anodizing. Compared with other acid anodizing, it has obvious advantages in terms of production cost, characteristics and performance of the oxide film. The main advantages are as follows: 1. Low production cost, sulfuric acid used in the electrolyte The price is low, electrolysis consumes less electricity, and waste liquid treatment is simple, making it a relatively cheap process;

The role of oxidation of aluminum alloy prototype

Determine whether to oxidize based on the usage of the part.

PROTO MFG provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.