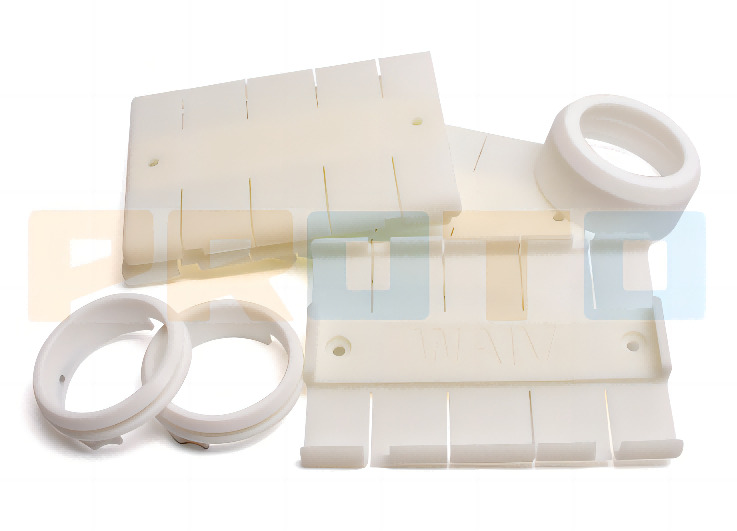

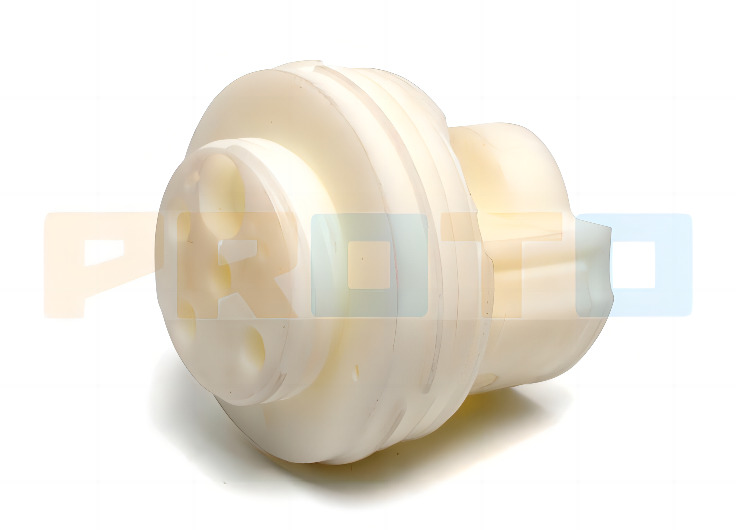

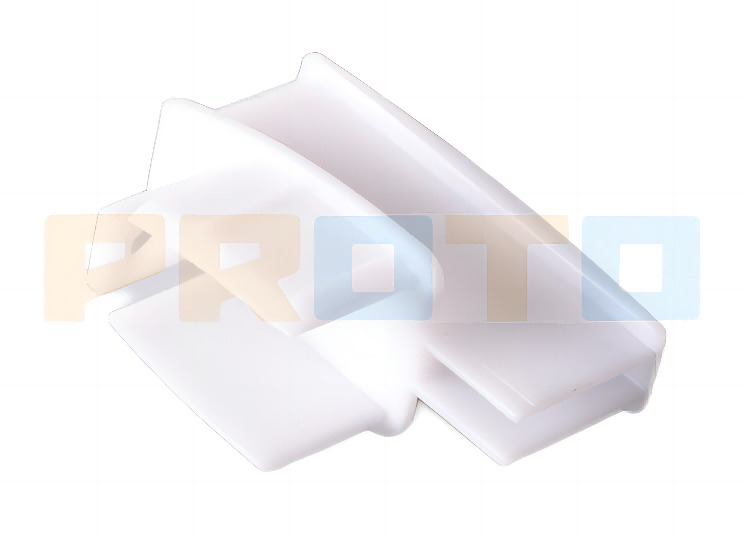

There are a variety of industrial parts and products that can be produced using plastic machining. These include biomedical and pharmaceutical devices, chemical handling equipment, food handling components, laboratory and scientific equipment, microelectronics, photonics and semiconductor components. Plastic machining can also be used for creating parts and products for the food and beverage industry, such as spray bars and assembly line pieces.

Plastic machined parts have several advantages over metal. Despite being thinner and lighter, plastic is highly durable and lasts longer since it is a good thermal insulator. In some cases, plastic parts can replace metal bearings due to their superior wear surfaces and lower friction. Plastic machined parts are also highly machinable and can be used for rapid prototyping, making them a highly popular material. Additionally, plastic machined parts are found in various industries, including waste and water treatment, where they are used for brushings, sprockets, wear pads, seals & saddles, rollers, valves, connectors, drainage units, catch basins, and more, thanks to their high durability, low porosity, and low friction.

PROTO MFG has several advantages when it comes to plastic machined parts. First, we use over 30 different materials, which means that we can customize your CNC plastic parts based on their application. Additionally, we use high-performance precision machining methods such as 5-axis CNC machining, allowing us to create detailed and accurate parts. Our machined plastic parts are suitable for use in a wide range of industries, from the military to the food production industry. Finally, our knowledge of plastic materials and their properties ensures that we can provide you with quality parts that meet your specifications.