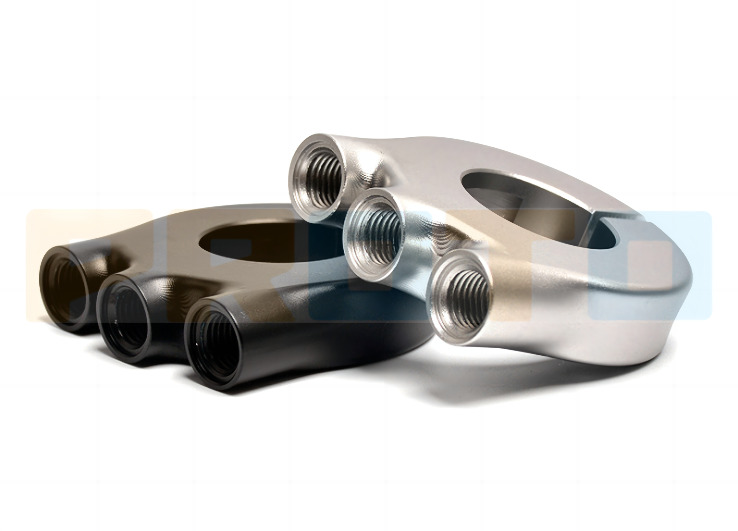

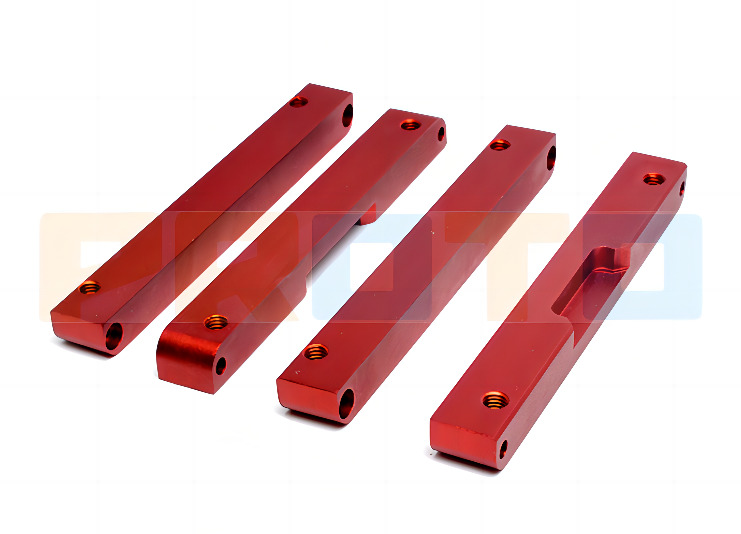

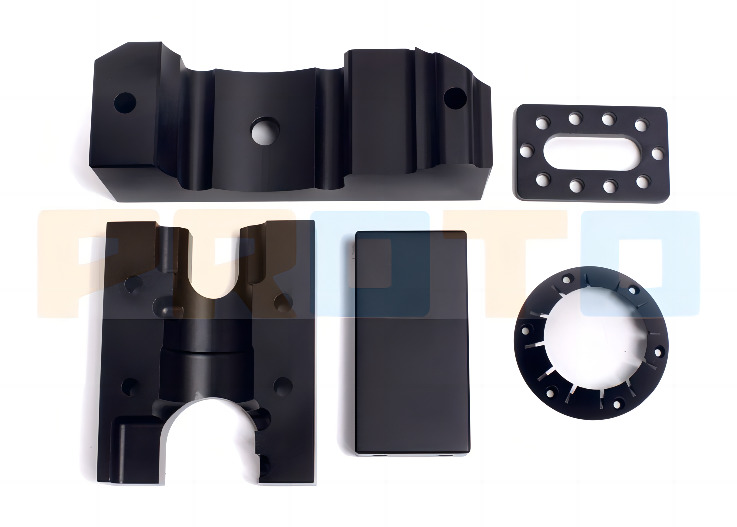

Anodizing Type II is an electrochemical process that produces a protective oxide layer on aluminum surfaces,

offering increased corrosion resistance and improved appearance.

Anodizing is a crucial step in the manufacturing of machined parts, especially machined aluminum parts. Type II anodizing is commonly used in various industries, including automotive, aerospace, and electronic components manufacturing. This process improves the mechanical and aesthetic properties of the machined parts, making them resistant to wear and tear and giving them an attractive finish. Type II anodizing also improves the corrosion resistance of the machined parts, making them more durable and long-lasting. It is a reliable and relatively inexpensive method to improve wear resistance and coloring of aluminum and other non-ferrous metals.