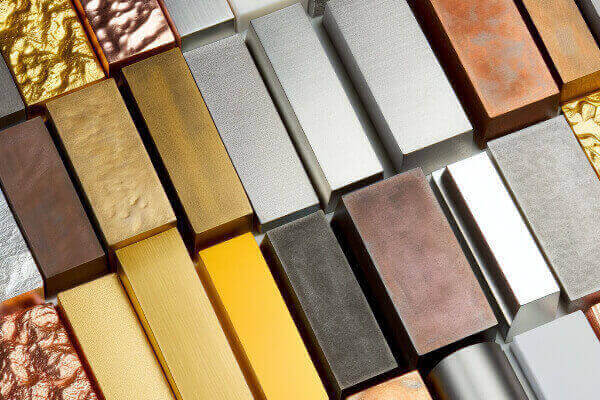

In the ever-evolving field of medicine, the choice of materials used in medical devices and equipment is crucial. Medical-friendly materials must meet strict standards for safety, biocompatibility, and performance, ensuring they do not cause adverse reactions when in contact with the human body. From surgical instruments to implants and diagnostic equipment, the materials used play a significant role in the effectiveness and reliability of medical devices. This article explores six of the most commonly used medical-friendly materials, highlighting their properties, applications, and benefits.

Stainless steel is one of the most widely used materials in the medical-friendly materials due to its excellent corrosion resistance, strength, and ease of sterilization. The most common types of stainless steel used in medical applications are 304 and 316 grades.

Stainless steel is commonly used in surgical tools, implants, dental instruments, and hospital equipment. Its ability to withstand sterilization processes further enhances its appeal in medical settings.

Titanium is a lightweight, strong, and biocompatible material widely used in the medical industry, especially for implants and prosthetics. Its unique properties make it an excellent choice for applications where strength and biocompatibility are critical.

Titanium is commonly used in orthopedic implants, dental implants, and prosthetics. Its lightweight nature and biocompatibility make it an ideal choice for long-term implantation in the body.

Polyethylene is a versatile thermoplastic polymer that is extensively used in medical applications. Its excellent chemical resistance, flexibility, and low-friction properties make it a popular choice for various medical devices.

Manufacturers use polyethylene in surgical implants, prosthetics, and various medical devices, such as tubing and containers. They often choose high-density polyethylene (HDPE) for its durability and chemical resistance.

Manufacturers recognize silicone as a synthetic rubber material known for its flexibility, biocompatibility, and resistance to extreme temperatures. They widely use it in medical devices and applications requiring elasticity and durability.

Silicone is commonly used in medical tubing, catheters, implants, and seals. Its versatility and safety make it an essential material in many medical devices.

Manufacturers often use glass in medical applications for its excellent clarity, chemical resistance, and ease of sterilization. While it may not be as common as other materials, its unique properties make it suitable for specific medical devices.

Manufacturers commonly use glass in laboratory equipment, such as test tubes and vials, as well as in optical devices and diagnostic tools. Its non-reactive nature makes it ideal for storing sensitive materials.

Ceramics are inorganic, non-metallic materials that exhibit excellent biocompatibility and wear resistance, making them suitable for specific medical applications. Manufacturers increasingly use advanced ceramics in the medical field due to their unique properties.

Manufacturers commonly use ceramics in dental implants, orthopedic implants, and various prosthetic devices.Their strength and biocompatibility make them ideal for long-term use in the body.

The choice of materials in the medical field is critical to ensuring the safety and efficacy of medical devices and equipment. Stainless steel, titanium, polyethylene, silicone, glass, and ceramics each offer unique properties that make them suitable for specific applications in medicine.

As the medical industry continues to evolve, researchers and manufacturers will continue to explore new materials and technologies to enhance patient care and improve medical outcomes. Selecting the right material for a particular application is essential, and partnering with a knowledgeable manufacturer like PROTO MFG can help ensure that the chosen material meets the necessary standards for safety, performance, and biocompatibility. Understanding these top medical-friendly materials and their applications will aid in making informed decisions in the design and manufacturing of medical devices.